In microbial and bacterial fermentations, the feed gas composition is relatively constant—either air or air enriched with oxygen. In mammalian cell fermentations, the feed gas composition is a frequently changing mixture of several compounds (e.g. nitrogen, oxygen and carbon dioxide).

In microbial and bacterial fermentations, the feed gas composition is relatively constant—either air or air enriched with oxygen. In mammalian cell fermentations, the feed gas composition is a frequently changing mixture of several compounds (e.g. nitrogen, oxygen and carbon dioxide).

The feed gas concentration ranges vary dramatically—for example carbon dioxide can vary from tens of parts per million to tens of percent. If an overlay gas is used this introduces further complications because the overall inlet gas composition is a combination of sparge gas and overlay gas. Also the use of sodium bicarbonate as a pH buffer can contribute to the carbon dioxide level in the outlet.

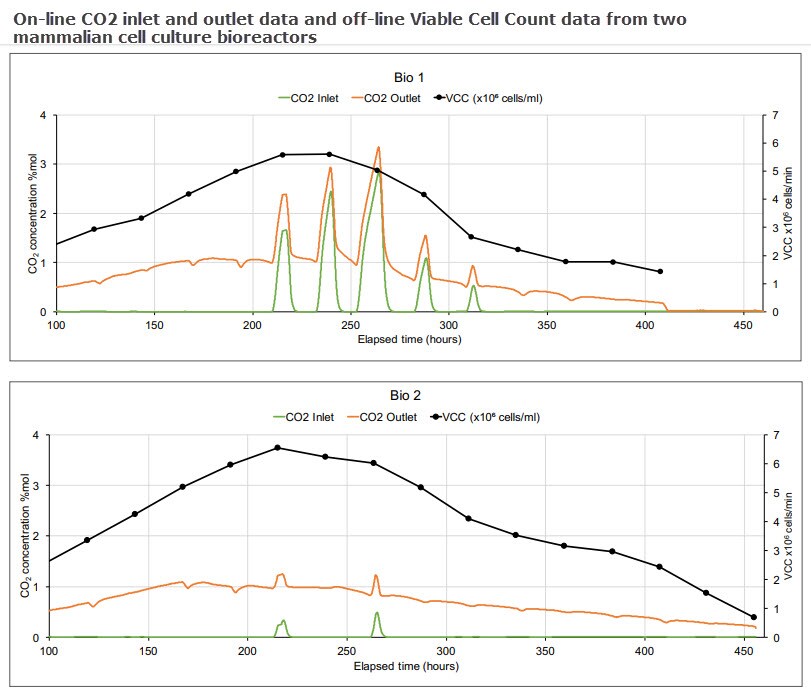

These factors all contribute to a challenging set of requirements for the off-gas analyzer if it is to provide meaningful on-line data to complement off-line data such as viable cell count and metabolite concentration data. The figure below illustrates how the magnetic sector’s speed and precision are able to provide this valuable data. A benchtop magnetic sector mass spectrometer monitored two 5 litre bioreactors in which modified Chinese Hamster Ovary (CHO) cells were used to express monoclonal antibodies.

The benchtop magnetic sector mass spectrometer analyzed inlet and outlet gases for O2, CO2, N2 and Ar on both bioreactors. Besides the on-line MS measurements, cell count (both total and viable), lactate levels and glucose levels were analyzed off-line. For each bioreactor there was just one inlet – the sparge gas, which was a combination of O2, CO2, N2 and Air. Oxygen feed was used to control the dissolved oxygen and carbon dioxide was used to control pH.

MS cycle time was 15 seconds per point including settling time, and concentrations were averaged over 99 readings to reduce noise caused by perturbations in sparge gas concentrations. As there is little activity at the beginning of the run, the figure above displays data from 100 hours onwards.

Although both bioreactors were controlled by the same controller, Bio 1 exhibits a very different inlet CO2 profile as significant quantities of CO2 were injected to adjust pH. The more stable CO2 profile in Bio 2 led to a higher Viable Cell Count and an extended culture duration; during subsequent runs the control strategy was modified, leading to further extensions in culture durations and increased VCC levels.

When it comes time to scale up from laboratory to bulk production, the manufacturing process typically begins with cell cultures grown in the laboratory. Then, during the scale-up process, cells are sequentially transferred to larger and larger fermentors, eventually into production vessels that can hold up to 20,000 litres of growth media and cells. It is vital to maintain the precise environment that specific cells need to remain healthy and grow – this requires precise off-gas analytical data through every stage of the scale up process, from laboratory to pilot plant to bulk production.

In some cases one mass spectrometer fitted with a suitable multi-stream inlet can monitor all the fermentors, in other cases separate MS analyzers have to be used in the laboratory and on the plant. It is critical that results from the two analyzer platforms correlate to ensure a smooth transition through the various stages of scale up

In general, key advantages of utilizing magnetic sector analyzers in fermentation and cell culture process include improved precision, accuracy, long intervals between calibrations and resistance to contamination. Benchtop magnetic sector mass spectrometers can also offer rapid multistream sampling when one has to monitor multiple bioreactors, measurement of oxygen, carbon dioxide, nitrogen and argon in both inlet and outlet to calculate the respiratory quotient for fermentation off-gas analysis, and analysis of volatiles that can yield vital information on the well-being of the fermentation. (You can read more specifics about these factors in the application note Gas analysis mass spectrometer applications in fermentation and cell culture process.)

Editor’s Notes:

- Free ebook: A Practical Guide to Improving Pharmaceutical and Biotech Manufacturing Processes and Production Methods

- Download the application note: Gas analysis mass spectrometer applications in fermentation and cell culture process

- Additional application notes, white papers, and other free resources are available in the Improved Quality and Productivity for Pharma and Biotech Manufacturing section of our website.

Leave a Reply