Proper sample preparation is a critical step in the scientific experiment process – one which can determine the ultimate quality and accuracy of the results. For experiments involving transmission electron microscopy (TEM), sample preparation has historically been a laborious, multiple step process.

As we celebrate 30 years of TEM sample preparation, it’s exciting to think how far this process has come. From the first focused ion beam (FIB) technology of three decades ago to the highly automated DualBeam innovations of today, TEM sample preparation has gradually transformed from a manual, time-consuming, and inconsistent process into one that is fully automated, fast, and highly reproducible—accelerating research and innovation in a wide variety of fields.

Sample Preparation for TEM analysis

To prepare a sample that can be imaged by a transmission electron microscope, researchers need to extract a thin lamella, typically between 10 and 100 nanometers thick, that contains the region of interest.

The sample needs to be representative of the bulk material, which means minimizing any preparation-induced artifacts, such as curtains, contamination, and surface and side-wall beam damage. Moreover, the sample needs to be the right thickness. If the sample is too thick, the area of interest might be blocked; if it’s too thin, the sample may be too fragile and key features could be lost.

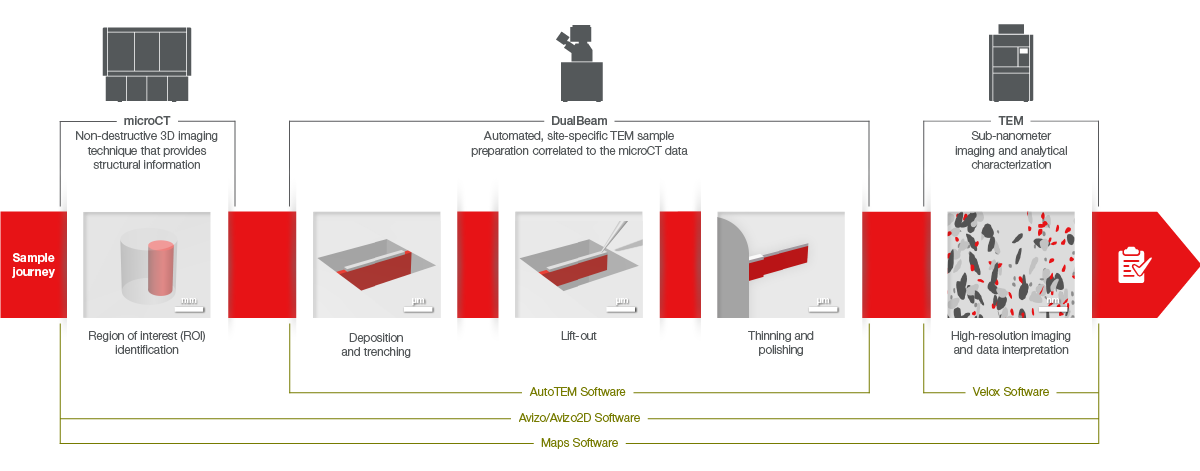

Characterization of novel advanced materials often require multi-scale, multi-modal correlative techniques such as microCT, DualBeam and TEM.

Traditional TEM sample preparation techniques

FIB first took off in the late 1980s and early 1990s, when multiple labs began to adopt this method, especially semiconductor labs that needed to identify defects discovered using other methods. Using a FIB-SEM, such as the first DualBeam introduced by FEI (now part of Thermo Fisher Scientific) in 1993, researchers could more easily prepare thin lamellae when it was impractical to do so using other methods, and then study an exact region of interest using high-resolution TEM imaging. This made it possible to isolate and analyze specific spots on a sample, like one faulty transistor among several millions on a semiconductor chip.

While FIB made it easier to obtain a “biopsy” of a material, it has historically been a time-consuming, manual process. Different samples from the same material often showed different results. The quality of the sample was dependent on the individual operator who required extensive practice before becoming an expert. Sample analyses required multiple tools and instruments making it difficult to obtain consistent results. As a result, sample prep typically required several days to prepare just one sample, keeping scientists from performing their actual analysis.

This photo shows an original FIB workstation. We developed the Thermo Fisher’s first single-beam Ga+ FIB, allowing sub-microscale site-specific material removal, enabling site specific sample preparation.

Saving time and increasing sample quality

Over the years, FEI and Thermo Fisher Scientific have improved TEM sample quality and increased throughput. In-situ lift-out features and advanced ion columns were added, and other capabilities were introduced that made DualBeam a more powerful instrument for analyzing material microstructures.

In the 2000s, for example, FEI released the Sidewinder and Tomahawk FIB columns, which improved polishing capabilities at low voltages. In the 2010s, FEI introduced the first Plasma FIB, leading to far higher bulk material removal rates and provided alternative (noble gas) ion species compared to the traditional gallium ion sources.

A fully automated process

Today, the Helios 5 DualBeam is the standard for TEM and STEM sample preparation. Helios 5 DualBeam instruments simplify the sample prep process and minimize the chance of human error. They also increase sample prep consistency, while Plasma FIB technology makes it possible to prepare samples without gallium implantation or contamination.

Many Helios 5 DualBeam instruments come with AutoTEM 5 Software, which automates the entire process of lamella preparation from chunking to in-situ lift-out, thinning, and final low- kilovolt polishing.

With AutoTEM Software, researchers of all skill levels can prepare even the most challenging TEM samples. Even better, they can do so in dramatically less time than the hours and days required in the past. Today, researchers can now prepare a sample for TEM analysis in as fast as 45 minutes using fully automated procedure, accelerating research in fields such as batteries, polymers, metals and more.

More time for more innovation

As we celebrate 30 years of TEM sample preparation, we’re thrilled by the tremendous progress over the last three decades. We appreciate the scientists who use our systems and those who provide the feedback that fuels innovation. Today, FIB sample prep has evolved into a fully automated, fast and repeatable process. Less time spent on TEM sample preparation means more time spent fabricating the high-quality materials and devices needed to advance our global society.

To learn more, visit our TEM Sample Preparation Techniques webpage.

//

Mikhail Dutka is the Product Marketing Manager for DualBeam instruments at Thermo Fisher Scientific.

This blog was also drafted with contributions from Brandon Van Leer, Richard Young and Remco Geurts, all who have been instrumental in developing and advancing the FIB sample preparation methods during the last couple of decades.

Teally SEM and TEM samples preparation need a lot of time in the samples preparation lab