The development and production of polymers and plastics requires rigorous quality control of raw materials, additives, stabilizers, intermediate and finished products. The analysis of their behaviour during moulding and the product lifetime evaluation is essential to ensure the quality of plastics. The chemical composition of plastics and polymers is tightly connected with their specific characteristics and their chemical/physical/mechanical properties.

The development and production of polymers and plastics requires rigorous quality control of raw materials, additives, stabilizers, intermediate and finished products. The analysis of their behaviour during moulding and the product lifetime evaluation is essential to ensure the quality of plastics. The chemical composition of plastics and polymers is tightly connected with their specific characteristics and their chemical/physical/mechanical properties.

One of the required analyses is the quantification of nitrogen, carbon, hydrogen, sulfur and oxygen. Nitrogen determination is crucial, but the importance of sulfur evaluation has increased in recent years, as many of the classical methods are no longer suitable for routine analysis.

Nitrogen containing compounds are used in the production process as a polymerization reaction. It can also act as termination agent and additive in order to provide the final product with specific properties.

As an additive, nitrogen containing compounds can be used as:

- Stabilizing emulsion polymers

- Chain transfer agents and other polymerization modifiers to control molecular weight

- Plasticizers to increase flexibility

- Stabilizers to prevent polymer degradation

- Crosslinkers used to modify polymer networks

As the specification of the element content is sometimes very limited, an accurate measurement is required in order to maximize sample throughput, reduce operational costs and minimize human errors. Therefore, a simple and automated technique, which enables fast analysis combined with excellent accuracy and reproducibility is essential.

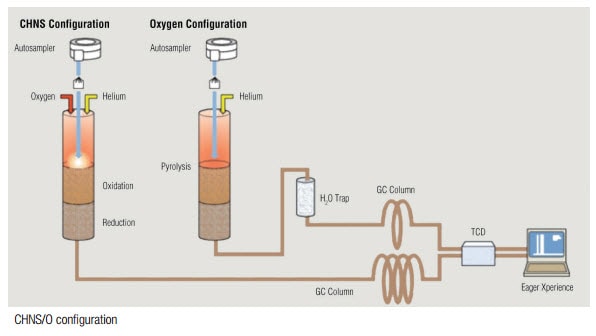

An Elemental Analyzer is a reliable system for quantification of carbon, hydrogen, nitrogen, sulfur, and oxygen. It requires no sample digestion or toxic chemicals, provides important advantages in terms of time, automation and quantitative determination across a large range of concentrations, till trace content. In order to prove that an elemental analyzer could provide accurate measurements, we conducted a study where different types of polymers and plastics, raw materials and additives were analyzed, considering the different content and aspect (pellets, powders and films).

An Elemental Analyzer, based on the Dumas combustion method, proved to be a valuable solution for the elemental analysis in polymers and plastics in terms of accuracy, repeatability and sensitivity of results. Its automation, high speed of analysis and the elimination of sample preparation process allowed efficient analysis and helped to reduce overall operational costs. The analysis was performed without matrix effect when changing the sample and element content indicating the complete combustion of the samples. With an upgrade, the Elemental Analyzer could determine nitrogen only, simultaneous CHNS, NCS, CHN and oxygen. Trace sulfur determination was achieved when the system was coupled with the FPD detector.

To see specifics about the study, including the method and instruments used, configurations, and tables of data, read the Characterization of Polymers and Plastics application note.

Links don’t work