Search Thermo Fisher Scientific

Materials Science

Catalysis Research

Catalyst nanoparticle imaging and analysis with electron microscopy and EDS.

Join the conversation

Catalysis research

Involved in the processing of over 80% of all manufactured products, catalysts are a critical aspect of modern industry. Heterogeneous nanoparticle catalysts, in particular, are important for a number of modern, environmentally friendly processes such as the production of hydrogen fuel and are found ubiquitously in automotive catalytic converters. As catalysts accelerate production rates and lower temperature requirements for relevant reactions, they significantly reduce the energy needed to perform a given process and/or produce a product of interest.

Nanoparticle catalysis

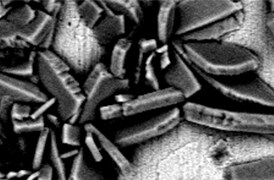

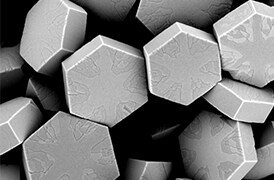

The morphology, distribution, size, and chemical composition of nanoparticles are crucial for their catalytic efficiency. Scanning transmission electron microscopy (S/TEM) combined with energy-dispersive X-ray spectroscopy (EDS) has proven to be a valuable research tool for the direct observation and quantification of this information. Additionally, high-performance scanning electron microscopy (SEM) tools take excellent images of beam-sensitive catalyst materials under low-beam-energy and low-beam-current conditions without causing sample damage.

Thermo Fisher Scientific provides a range of instrumentation ideally suited for the characterization of catalyst nanoparticles. We also offer a suite of software tools that allow you to automate your workflow, generating high-resolution, large-area nanoparticle data for a holistic overview of your catalyst.

High-resolution EDS maps of a beam-sensitive material used for photocatalytic processes (C3N4(Co)-Pt). The catalyst uses the synergistic behavior of platinum and cobalt nanoparticles to improve catalytic efficiency. Data courtesy of Prof. ShengChun Yang, Xi’an Jiaotong University, China.

On-Demand Webinar: Spectra 200 S/TEM: A workhorse for catalyst characterisation

Watch this webinar to learn advanced catalyst characterisation methods using TEM, how tools like the Spectra 200 S/TEM are used in the catalyst industry and why Haldor Topsøe chooses the Spectra 200 S/TEM.

On-Demand Webinar: Quantitative structural analysis using STEM HAADF-iDPC

This webinar will give an introduction to the relevance of materials in catalysis, the challenges in their synthesis and their characterisation at atomic level.

On-Demand Webinar: Spectra 200 S/TEM: A workhorse for catalyst characterisation

Watch this webinar to learn advanced catalyst characterisation methods using TEM, how tools like the Spectra 200 S/TEM are used in the catalyst industry and why Haldor Topsøe chooses the Spectra 200 S/TEM.

On-Demand Webinar: Quantitative structural analysis using STEM HAADF-iDPC

This webinar will give an introduction to the relevance of materials in catalysis, the challenges in their synthesis and their characterisation at atomic level.

Process control using electron microscopy

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

(S)TEM Sample Preparation

DualBeam microscopes enable the preparation of high-quality, ultra-thin samples for (S)TEM analysis. Thanks to advanced automation, users with any experience level can obtain expert-level results for a wide range of materials.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

_Technique_800x375_144DPI.jpg)

3D EDS Tomography

Modern materials research is increasingly reliant on nanoscale analysis in three dimensions. 3D characterization, including compositional data for full chemical and structural context, is possible with 3D EM and energy dispersive X-ray spectroscopy.

Energy Dispersive Spectroscopy

Energy dispersive spectroscopy (EDS) collects detailed elemental information along with electron microscopy images, providing critical compositional context for EM observations. With EDS, chemical composition can be determined from quick, holistic surface scans down to individual atoms.

Atomic-Scale Elemental Mapping with EDS

Atomic-resolution EDS provides unparalleled chemical context for materials analysis by differentiating the elemental identity of individual atoms. When combined with high-resolution TEM, it is possible to observe the precise organization of atoms in a sample.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

_Technique_800x375_144DPI.jpg)

Differential Phase Contrast Imaging

Modern electronics research relies on nanoscale analysis of electric and magnetic properties. Differential phase contrast STEM (DPC-STEM) can image the strength and distribution of magnetic fields in a sample and display the magnetic domain structure.

Imaging Hot Samples

Studying materials in real-world conditions often involves working at high temperatures. The behavior of materials as they recrystallize, melt, deform, or react in the presence of heat can be studied in situ with scanning electron microscopy or DualBeam tools.

_Technique_800x375_144DPI.jpg)

Environmental SEM (ESEM)

Environmental SEM allows materials to be imaged in their native state. This is ideally suited for academic and industrial researchers who need to test and analyze samples that are wet, dirty, reactive, outgassing or otherwise not vacuum compatible.

Electron Energy Loss Spectroscopy

Materials science research benefits from high-resolution EELS for a wide range of analytical applications. This includes high-throughput, high signal-to-noise-ratio elemental mapping, as well as probing of oxidation states and surface phonons.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

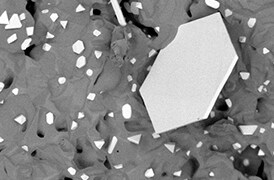

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

SIMS

The TOF-SIMS (time-of-flight secondary ion mass spectrometry) detector for focused ion beam scanning electron microscopy (FIB-SEM) tools enables high-resolution analytical characterization of all elements in the periodic table, even at low concentrations.

Multi-scale analysis

Novel materials must be analyzed at ever higher resolution while retaining the larger context of the sample. Multi-scale analysis allows for the correlation of various imaging tools and modalities such as X-ray microCT, DualBeam, Laser PFIB, SEM and TEM.

X-Ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy (XPS) enables surface analysis, providing elemental composition as well as the chemical and electronic state of the top 10 nm of a material. With depth profiling, XPS analysis extends to compositional insight of layers.

The Automated NanoParticle Workflow (APW) is a transmission electron microscope workflow for nanoparticle analysis, offering large area, high resolution imaging and data acquisition at the nanoscale, with on-the-fly processing.

(S)TEM Sample Preparation

DualBeam microscopes enable the preparation of high-quality, ultra-thin samples for (S)TEM analysis. Thanks to advanced automation, users with any experience level can obtain expert-level results for a wide range of materials.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

_Technique_800x375_144DPI.jpg)

3D EDS Tomography

Modern materials research is increasingly reliant on nanoscale analysis in three dimensions. 3D characterization, including compositional data for full chemical and structural context, is possible with 3D EM and energy dispersive X-ray spectroscopy.

Energy Dispersive Spectroscopy

Energy dispersive spectroscopy (EDS) collects detailed elemental information along with electron microscopy images, providing critical compositional context for EM observations. With EDS, chemical composition can be determined from quick, holistic surface scans down to individual atoms.

Atomic-Scale Elemental Mapping with EDS

Atomic-resolution EDS provides unparalleled chemical context for materials analysis by differentiating the elemental identity of individual atoms. When combined with high-resolution TEM, it is possible to observe the precise organization of atoms in a sample.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

_Technique_800x375_144DPI.jpg)

Imaging using HRSTEM and HRTEM

Transmission electron microscopy is invaluable for characterizing the structure of nanoparticles and nanomaterials. High-resolution STEM and TEM enable atomic-resolution data along with information on chemical composition.

_Technique_800x375_144DPI.jpg)

Differential Phase Contrast Imaging

Modern electronics research relies on nanoscale analysis of electric and magnetic properties. Differential phase contrast STEM (DPC-STEM) can image the strength and distribution of magnetic fields in a sample and display the magnetic domain structure.

Imaging Hot Samples

Studying materials in real-world conditions often involves working at high temperatures. The behavior of materials as they recrystallize, melt, deform, or react in the presence of heat can be studied in situ with scanning electron microscopy or DualBeam tools.

_Technique_800x375_144DPI.jpg)

Environmental SEM (ESEM)

Environmental SEM allows materials to be imaged in their native state. This is ideally suited for academic and industrial researchers who need to test and analyze samples that are wet, dirty, reactive, outgassing or otherwise not vacuum compatible.

Electron Energy Loss Spectroscopy

Materials science research benefits from high-resolution EELS for a wide range of analytical applications. This includes high-throughput, high signal-to-noise-ratio elemental mapping, as well as probing of oxidation states and surface phonons.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

SIMS

The TOF-SIMS (time-of-flight secondary ion mass spectrometry) detector for focused ion beam scanning electron microscopy (FIB-SEM) tools enables high-resolution analytical characterization of all elements in the periodic table, even at low concentrations.

Multi-scale analysis

Novel materials must be analyzed at ever higher resolution while retaining the larger context of the sample. Multi-scale analysis allows for the correlation of various imaging tools and modalities such as X-ray microCT, DualBeam, Laser PFIB, SEM and TEM.

X-Ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy (XPS) enables surface analysis, providing elemental composition as well as the chemical and electronic state of the top 10 nm of a material. With depth profiling, XPS analysis extends to compositional insight of layers.

The Automated NanoParticle Workflow (APW) is a transmission electron microscope workflow for nanoparticle analysis, offering large area, high resolution imaging and data acquisition at the nanoscale, with on-the-fly processing.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.