Search Thermo Fisher Scientific

_Hero_1440x390_144DPI.jpg)

Materials Science

Environmental Scanning Electron Microscopy

Environmental scanning electron microscopes are used for imaging wet, dirty, outgassing, and reactive materials in their natural state.

Join the conversation

Environmental scanning electron microscopy

size distribution analysis and easy sample preparation.

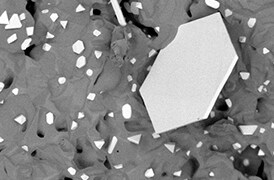

Horizontal field width = 2.56 μm.

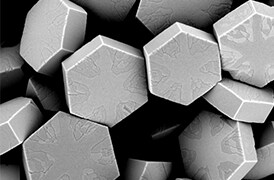

Modern materials science research has moved beyond traditional metals and coated samples. Today, there is a need for micro- and nano-scale information on more complex, challenging materials, including those that are nonconductive, dirty, wet, chemically reactive, or outgassing.

While electron microscopy (EM) has long been the benchmark for materials structural analysis, it has been limited to samples that are stable under vacuum. This generally does not represent the conditions experienced by the material in its native operating environment and can limit your understanding of its properties and behavior. Truly relevant observations, therefore, require high-resolution imaging and analysis under various experimental and environmental conditions. Sample preparation would ideally also be minimized to preserve the original state of the material.

Environmental scanning electron microscopy (ESEM) expands the boundaries of traditional SEM to deliver deeper insights into all types of samples. ESEM allows for imaging of samples with minimal preparation and adds variables such as hydration, thermal cycling, and the introduction of gas to characterize in situ dynamic changes. Using water vapor and a temperature control stage, some of the “impossible to image samples” such as dirty (highly outgassing) and naturally hydrated samples (whose properties will change with drying) are now easily characterized.

Environmental scanning electron microscopes

With full control of sample hydration, materials and life scientists can observe real-time material interactions in solution, along with how humidity changes a material and how water interacts with the sample surface. This moves research possibilities from pure static points in time to dynamic or in situ experimentation.

ESEM can be performed on our flexible and easy-to-use platforms without compromising on resolution. These ultra-versatile high-resolution SEMs combine all-around performance in imaging and analytics with an environmental mode that allows you to study samples in their natural state.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Battery Research

Battery development is enabled by multi-scale analysis with microCT, SEM and TEM, Raman spectroscopy, XPS, and digital 3D visualization and analysis. Learn how this approach provides the structural and chemical information needed to build better batteries.

Polymers Research

Polymer microstructure dictates the material’s bulk characteristics and performance. Electron microscopy enables comprehensive microscale analysis of polymer morphology and composition for R&D and quality control applications.

Metals Research

Effective production of metals requires precise control of inclusions and precipitates. Our automated tools can perform a variety of tasks critical for metal analysis including; nanoparticle counting, EDS chemical analysis and TEM sample preparation.

Oil and Gas

As the demand for oil and gas continues, there is an ongoing need for efficient and effective extraction of hydrocarbons. Thermo Fisher Scientific offers a range of microscopy and spectroscopy solutions for a variety of petroleum science applications.

Forensics

Micro-traces of crime scene evidence can be analyzed and compared using electron microscopy as part of a forensic investigation. Compatible samples include glass and paint fragments, tool marks, drugs, explosives, and GSR (gunshot residue).

Geological Research

Geoscience relies on consistent and accurate multi-scale observation of features within rock samples. SEM-EDS, combined with automation software, enables direct, large-scale analysis of texture and mineral composition for petrology and mineralogy research.

Catalysis Research

Catalysts are critical for a majority of modern industrial processes. Their efficiency depends on the microscopic composition and morphology of the catalytic particles; EM with EDS is ideally suited for studying these properties.

Fibers and Filters

The diameter, morphology and density of synthetic fibers are key parameters that determine the lifetime and functionality of a filter. Scanning electron microscopy (SEM) is the ideal technique for quickly and easily investigating these features.

Automotive Materials Testing

Every component in a modern vehicle is designed for safety, efficiency, and performance. Detailed characterization of automotive materials with electron microscopy and spectroscopy informs critical process decisions, product improvements, and new materials.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.