Search Thermo Fisher Scientific

Quattro Environmental Scanning Electron Microscope

The Thermo Scientific Quattro ESEM combines all-around performance in imaging and analytics with a unique environmental mode (ESEM) that allows samples to be studied in their natural state. It is ideal for a wide variety of academic, industrial, and government labs that want the versatility and ease of use needed for multiple users of different experience levels and disciplines on a platform that also supports unique in situ experiments. The Quattro ESEM features a field emission gun (FEG), which ensures excellent resolution. Meanwhile, its three vacuum modes (high vacuum, low vacuum, and ESEM) provide the flexibility to accommodate the widest range of samples of any SEM available, including those that are outgassing or otherwise not vacuum-compatible.

Learn more about this product in our on-demand webinar

Discover how to analyze liquids and hydrated samples in 3D using environmental scanning electron microscopy.

Best in class for in situ imaging capabilities, dynamic experiments with excellent analytical capabilities

The Quattro ESEM is a highly flexible platform for in situ dynamic experiments. The Quattro ESEM's environmental SEM capability allows scientists to study materials in a range of conditions, such as wet/humid, hot, or reactive environments, as they develop new materials and products. It supports cooling and heating experiments both in high vacuum and low vacuum to accommodate the widest range of needs. Cooling experiments on wet materials are possible with the Peltier cooling stage or if the transmission mode is needed, with Thermo Scientific WetSTEM Technology. Additionally, the Quattro ESEM provides several different possibilities to heat the samples of interest, both bulk and powders. Users can perform dynamic experiments at high temperatures both in high vacuum (with the high-vacuum heating stage), in low-vacuum/ESEM mode (with the two ESEM heating stages for temperatures up to 1,000°C and 1,400°C), and on a localized area for better control of the temperature change (with the Thermo Scientific µHeater Holder).

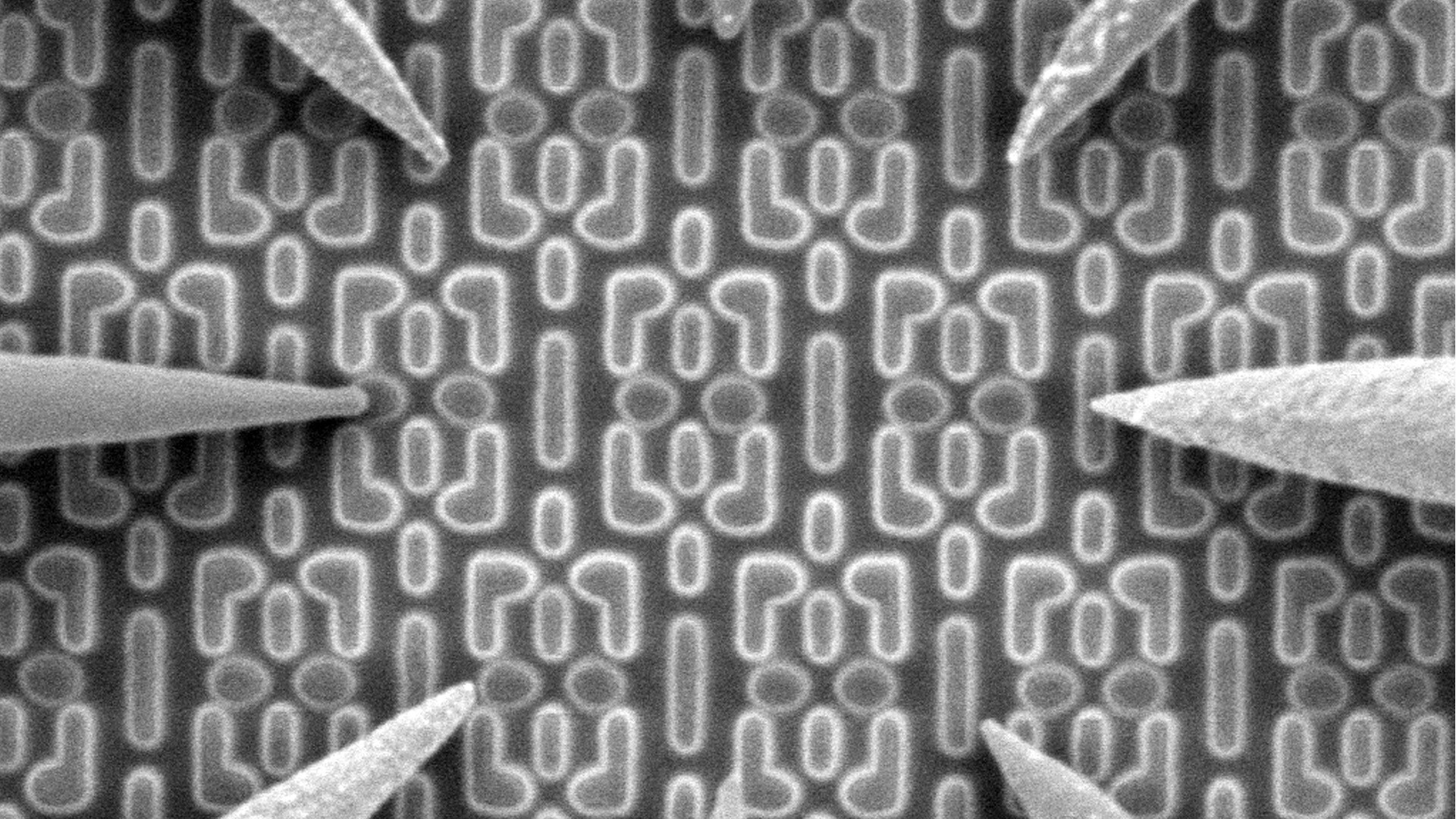

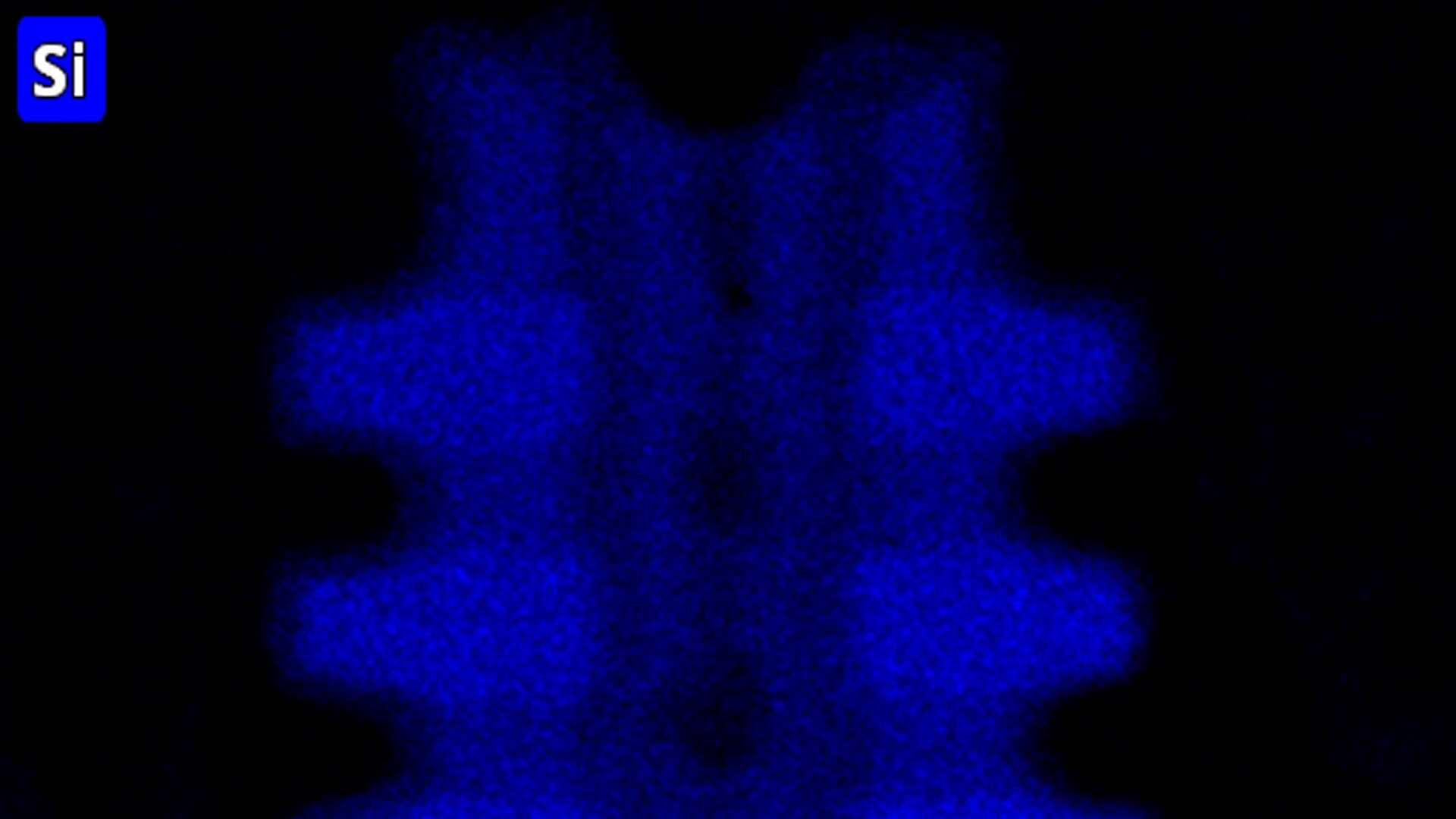

Thanks to the Quattro ESEM chamber size, it accommodates a wide range of accessories. Analytical capabilities include energy dispersive X-ray spectroscopy (EDS) with ports for 180-degree dual EDS attachment, electron backscatter diffraction (EBSD) coplanar with EDS, and wavelength dispersive X-ray spectroscopy (WDS). Furthermore, the Quattro ESEM comes with the new Thermo Scientific ChemiSEM Technology, a unique live elemental imaging capability that is fully integrated into the SEM user interface, providing always-available compositional information through the most intuitive interface.

Diverse material application observed with the Quattro ESEM

Dynamic in situ experiments

In situ study of materials in their natural state: unique high-resolution FEG-SEM with environmental mode (ESEM). In situ analysis at temperatures ranging from -165°C to 1,400°C with a range of cryo, Peltier, and heating stages.

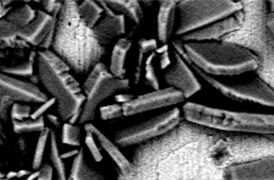

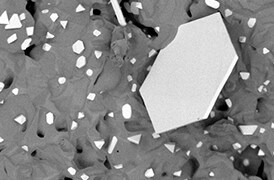

Peltier cooling experiment of sodium sulfate crystals in sandstone.

In situ cooling experiment conducted on a sandstone sample with crystals of sodium sulfate. The target of the experiment was to study the sodium sulfate behavior when completely hydrated. The pressure was varied up to 700 Pa, maintaining the temperature at 2˚C. Sample courtesy of Institute of Theoretical and Applied Mechanics of the Academy of Science, Czech Republic.

μHeater Holder heating experiment of magnetite and hematite.

Heating experiment run with the μHeater Holder. The video shows the heating of a mix of magnetite and hematite from 40˚C up to 1,000˚C.

Wide range of information

Observe all information from all samples with simultaneous SE and BSE imaging in every mode of operation. Several additional detectors, such as the STEM3+ detector and the retractable RGB cathodoluminescence (CL) detector are available to accommodate every user’s need and provide a complete set of information from a wide range of materials.

Excellent analytical capabilities

Excellent analytical capabilities with a flexible chamber that allows multiple EDS, EBSD, or WDS detectors. Elemental information at your fingertips with ChemiSEM Technology, which provides live, quantitative, elemental mapping for unprecedented time to result and ease of use. Excellent analysis of non-conductive samples: accurate EDS and EBSD are enabled in low vacuum with the Quattro ESEM's through-the-lens pumping.

Minimize sample preparation time with the unique combination of high-vacuum, low-vacuum, and environmental modes

Ease of use with innovative options and advanced automation

Easy to use, intuitive software with User Guidance. The unique Undo function permits efficient exploration of imaging conditions and allows you to work faster with fewer mouse clicks.

Advanced automation

Advanced automation is provided in different ways, with either Thermo Scientific AutoScript 4 Software or Thermo Scientific Maps Software, depending on the specific application needs.

AutoScript 4 Software offers control of the Quattro ESEM. Take advantage of a Python-based application programming interface (API) to optimize your in situ cooling or heating experiments or record and monitor dynamic parameters such as temperature, stage position, or pressure.

Maps Software automates large-area acquisition on multiple samples with up to four different simultaneous signals. In addition to a clear increase in the system productivity, it offers a multi-scale, multi-layered visualization environment in which 2D and 3D data and imagery can be imported from any source to correlate different modalities.

ESEM heating stage experiment on a silver wire, heated from 300˚C to 530˚C. AutoScript 4 Software was used to obtain a live drift compensation through a combination of beam shift and stage moves. The result was a stable image of the silver wire for the whole duration of the movie, even when the wire changed location over the substrate.

| Resolution |

|

| Standard detectors |

|

| Optional detectors |

|

| ChemiSEM Technology (optional) |

|

| Stage bias (beam deceleration, optional) |

|

| Low vacuum mode |

|

| Stage |

|

| Standard sample holder |

|

| Chamber |

|

| In situ accessories (optional) |

|

| Software options |

|

ESEM cooling experiment on coated filter paper, showing the paper’s behavior when fully hydrated.

WetSTEM cooling experiment on a flower and pollen sample. Thanks to the flexible design of this stage, it allows the characterization both in transmission mode and in top-down mode.

Peltier cooling experiment on food gelatin. The video shows the microstructural changes of the gelatine when frozen down to -10˚C.

Heating experiment ran with the μHeater system. The video shows the heating of a mix of magnetite and hematite from 40˚C up to 1000˚C.

Metals heating with the high vacuum heating stage. the video shows how the melted gold moves over the other materials while the heating progresses.

Cooling experiment conducted with the Peltier cooling stage. It shows the hydration of mold spores from a cheese sample.

In-situ cooling experiment conducted on a sandstone sample with crystals of sodium sulphate, to study its behavior when completely hydrated. Sample courtesy of Institute of Theoretical and Applied Mechanics of the Academy of Science, Czech Republic.

In-situ cooling experiment conducted on a sandstone sample with crystals of sodium sulphate, to study its behavior when completely hydrated. Sample courtesy of Institute of Theoretical and Applied Mechanics of the Academy of Science, Czech Republic.

ESEM heating stage experiment on a silver wire, heated from 300˚C to 530˚C. Autoscript 4 was used to obtain a live drift compensation through a combination of beam shift and stage moves.

Heating of a solder wire from 200˚C to 350˚C ran with the high vacuum heating stage.

TiAl TNM-B1 alloy heating with the high vacuum heating stage. The alloy was heated from room temperature up to 1100˚C showing oxidation and phase changes on the surface.

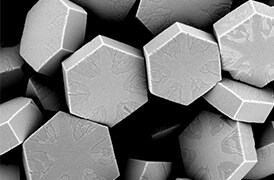

μHeater heating experiment on zinc oxide platelets. The progressive heating up to 1000˚C shows the textural changes of the platelet.

Webinar: Scanning electron microscopy: selecting the right technology for your needs

This on-demand webinar has been designed to help you decide which SEM best meets your unique needs. We present an overview of Thermo Fisher Scientific SEM technology for multi-user research labs and focus on how these wide-ranging solutions deliver performance, versatility, in situ dynamics and faster time to results. Watch this webinar if you are interested in:

- How the needs for different microanalysis modalities are met (EDX, EBSD, WDS, CL, etc.).

- How samples are characterized in their natural state without the need for sample preparation.

- How new advanced automation allows researchers to save time and increase productivity.

ESEM cooling experiment on coated filter paper, showing the paper’s behavior when fully hydrated.

WetSTEM cooling experiment on a flower and pollen sample. Thanks to the flexible design of this stage, it allows the characterization both in transmission mode and in top-down mode.

Peltier cooling experiment on food gelatin. The video shows the microstructural changes of the gelatine when frozen down to -10˚C.

Heating experiment ran with the μHeater system. The video shows the heating of a mix of magnetite and hematite from 40˚C up to 1000˚C.

Metals heating with the high vacuum heating stage. the video shows how the melted gold moves over the other materials while the heating progresses.

Cooling experiment conducted with the Peltier cooling stage. It shows the hydration of mold spores from a cheese sample.

In-situ cooling experiment conducted on a sandstone sample with crystals of sodium sulphate, to study its behavior when completely hydrated. Sample courtesy of Institute of Theoretical and Applied Mechanics of the Academy of Science, Czech Republic.

In-situ cooling experiment conducted on a sandstone sample with crystals of sodium sulphate, to study its behavior when completely hydrated. Sample courtesy of Institute of Theoretical and Applied Mechanics of the Academy of Science, Czech Republic.

ESEM heating stage experiment on a silver wire, heated from 300˚C to 530˚C. Autoscript 4 was used to obtain a live drift compensation through a combination of beam shift and stage moves.

Heating of a solder wire from 200˚C to 350˚C ran with the high vacuum heating stage.

TiAl TNM-B1 alloy heating with the high vacuum heating stage. The alloy was heated from room temperature up to 1100˚C showing oxidation and phase changes on the surface.

μHeater heating experiment on zinc oxide platelets. The progressive heating up to 1000˚C shows the textural changes of the platelet.

Webinar: Scanning electron microscopy: selecting the right technology for your needs

This on-demand webinar has been designed to help you decide which SEM best meets your unique needs. We present an overview of Thermo Fisher Scientific SEM technology for multi-user research labs and focus on how these wide-ranging solutions deliver performance, versatility, in situ dynamics and faster time to results. Watch this webinar if you are interested in:

- How the needs for different microanalysis modalities are met (EDX, EBSD, WDS, CL, etc.).

- How samples are characterized in their natural state without the need for sample preparation.

- How new advanced automation allows researchers to save time and increase productivity.

Process control using electron microscopy

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Semiconductor research and development

Innovation starts with research and development. Learn more about solutions to help you understand innovative structures and materials at the atomic level.

Semiconductor metrology

Manufacturing today’s complex semiconductors requires exact process controls. Learn more about advanced metrology and analysis solutions to accelerate yield learnings.

Semiconductor Failure Analysis

Complex semiconductor device structures result in more places for defects to hide. Learn more about failure analysis solutions to isolate, analyze, and repair defects.

Semiconductor materials characterization

Many factors impact yield, performance, and reliability. Learn more about solutions to characterize physical, structural, and chemical properties.

Energy Dispersive Spectroscopy

Energy dispersive spectroscopy (EDS) collects detailed elemental information along with electron microscopy images, providing critical compositional context for EM observations. With EDS, chemical composition can be determined from quick, holistic surface scans down to individual atoms.

Imaging Hot Samples

Studying materials in real-world conditions often involves working at high temperatures. The behavior of materials as they recrystallize, melt, deform, or react in the presence of heat can be studied in situ with scanning electron microscopy or DualBeam tools.

_Technique_800x375_144DPI.jpg)

Environmental SEM (ESEM)

Environmental SEM allows materials to be imaged in their native state. This is ideally suited for academic and industrial researchers who need to test and analyze samples that are wet, dirty, reactive, outgassing or otherwise not vacuum compatible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

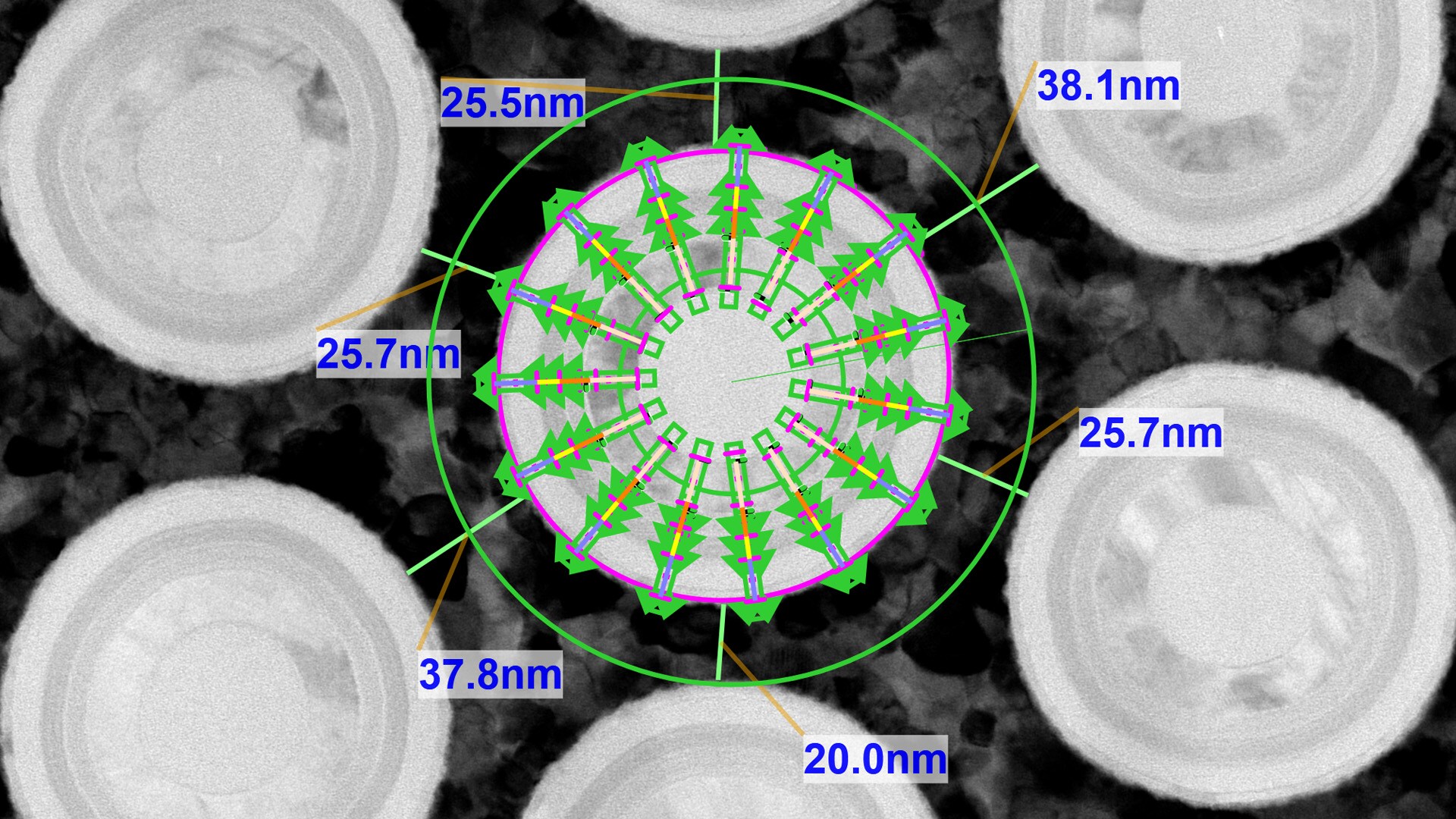

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

Cathodoluminescence

Cathodoluminescence (CL) describes the emission of light from a material when it is excited by an electron beam. This signal, captured by a specialized CL detector, carries information on the sample’s composition, crystal defects, or photonic properties.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

Semiconductor Analysis and Imaging

Thermo Fisher Scientific offers scanning electron microscopes for every function of a semiconductor lab, from general imaging tasks to advanced failure analysis techniques requiring precise voltage-contrast measurements.

Imaging Hot Samples

Studying materials in real-world conditions often involves working at high temperatures. The behavior of materials as they recrystallize, melt, deform, or react in the presence of heat can be studied in situ with scanning electron microscopy or DualBeam tools.

_Technique_800x375_144DPI.jpg)

Environmental SEM (ESEM)

Environmental SEM allows materials to be imaged in their native state. This is ideally suited for academic and industrial researchers who need to test and analyze samples that are wet, dirty, reactive, outgassing or otherwise not vacuum compatible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

Semiconductor Analysis and Imaging

Thermo Fisher Scientific offers scanning electron microscopes for every function of a semiconductor lab, from general imaging tasks to advanced failure analysis techniques requiring precise voltage-contrast measurements.

Electron microscopy services

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.