Search Thermo Fisher Scientific

- Order Status

- Quick Order

-

Don't have an account ? Create Account

Search Thermo Fisher Scientific

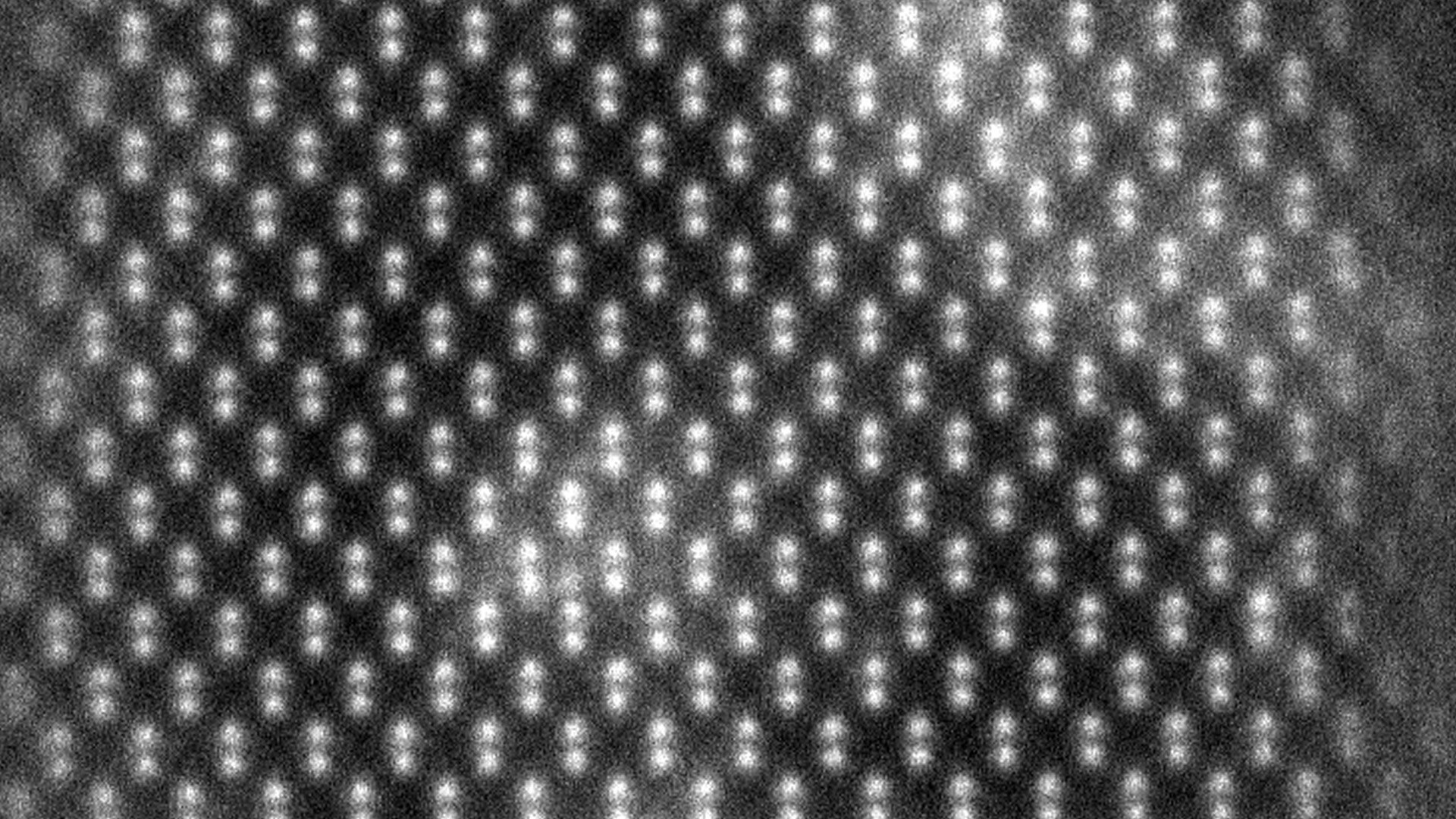

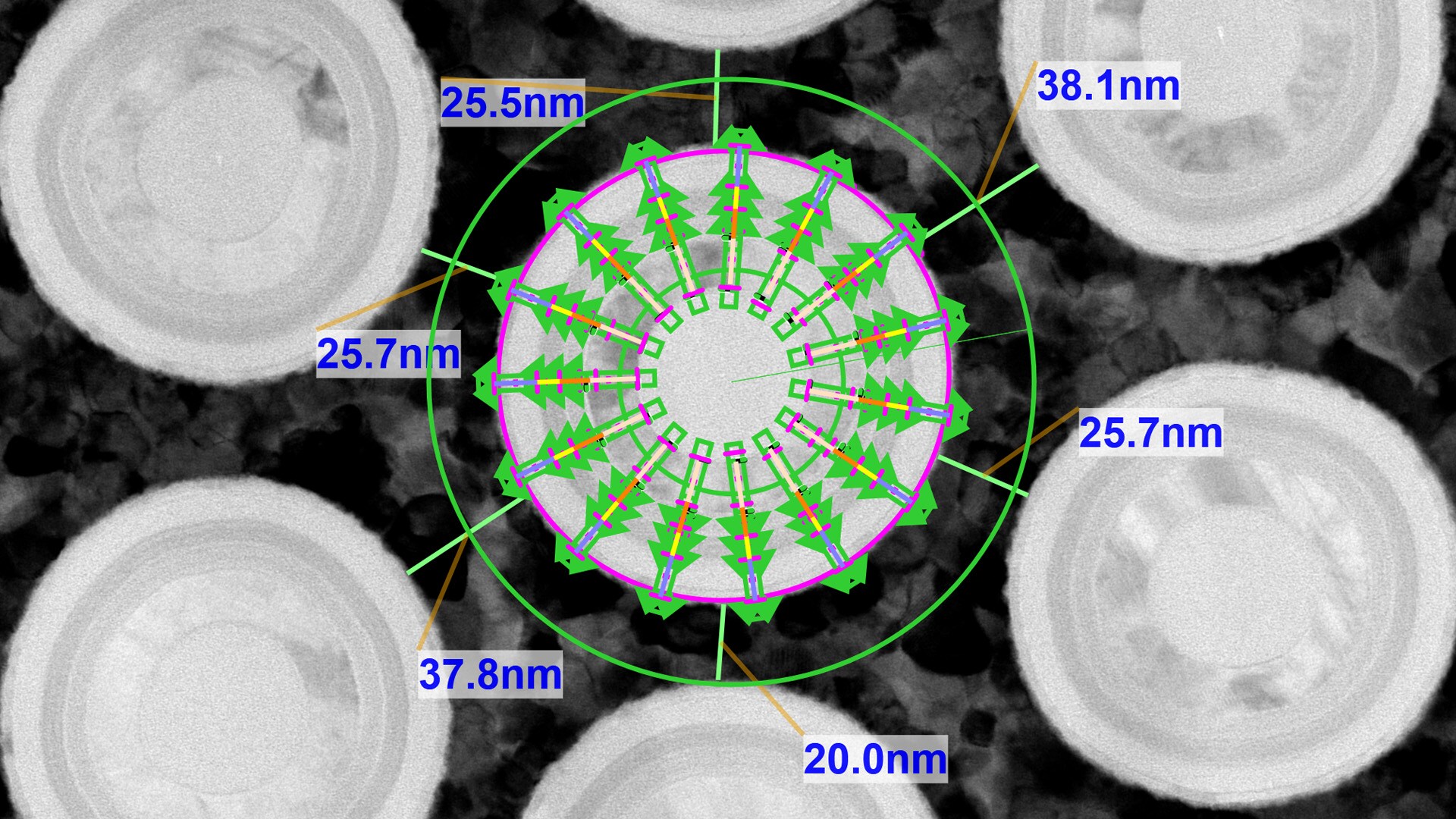

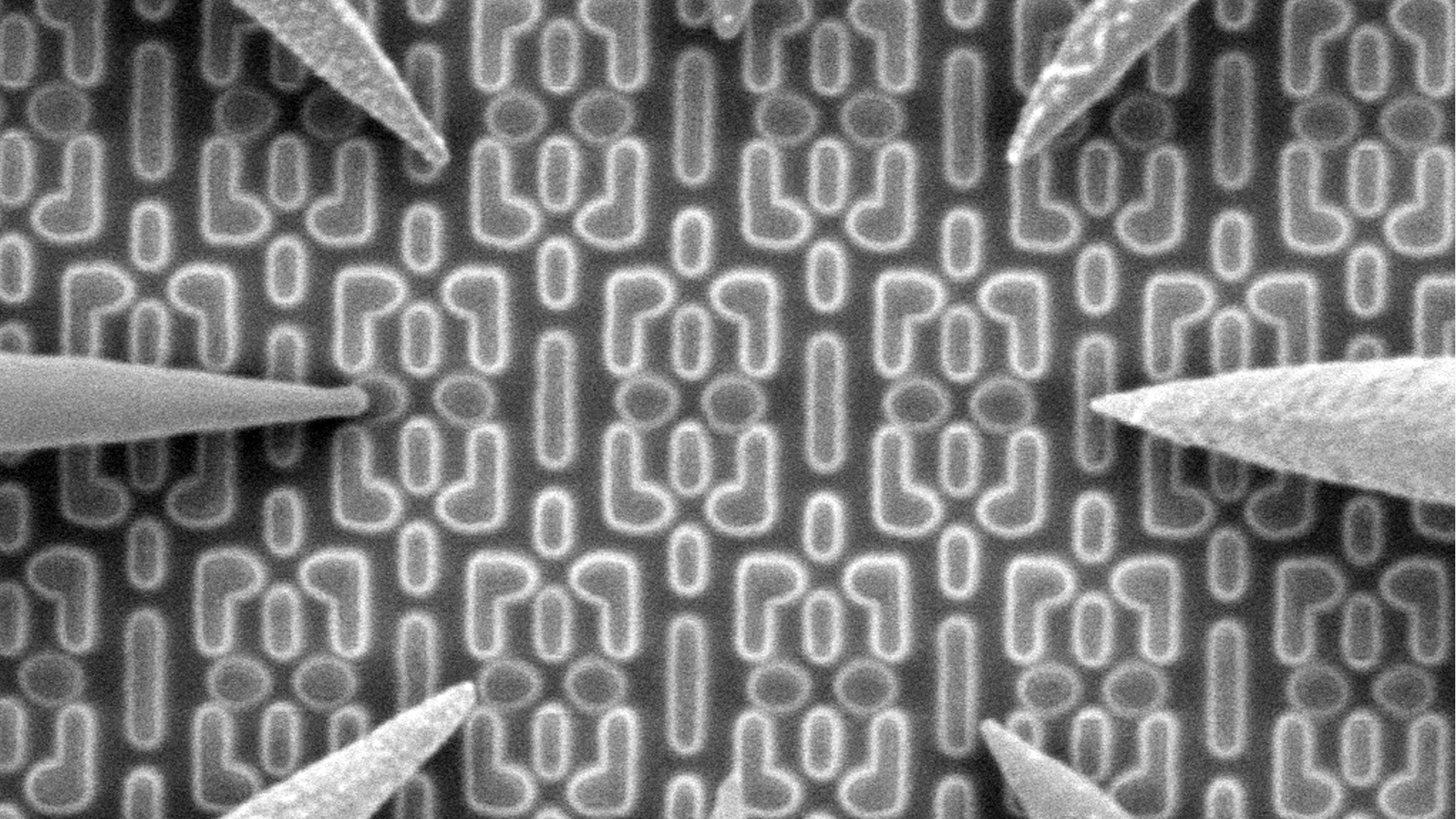

Advanced logic and memory manufacturing processes are becoming more reliant on fast turnaround of precise structural and analytical data to be able to quickly calibrate tool sets, diagnose yield excursions, and optimize process yields. At technology nodes below 28nm, especially in cases where 3D and advanced device designs are being implemented, conventional SEM or optical-based analysis and inspection tools run into challenges that limit their ability to provide robust and reliable data. The Thermo Scientific Metrios AX transmission electron microscope (TEM) is the first TEM dedicated to providing the fast, precise characterization and reference metrology that semiconductor manufacturers need to develop and control their wafer fabrication processes in order to accelerate profitable yield.

The Metrios AX TEM automates the basic TEM operation and measurement procedures, minimizing the requirements for specialized operator training. Its advanced automated metrology routines deliver significantly greater precision than manual methods. The Metrios AX TEM is designed to provide improved throughput and lower cost-per-sample than other TEMs.

Designed from the ground-up to deliver repeatable TEM and STEM-based imaging, analytics and gauge capable metrology.

Less than 0.75% combined error in distortion and magnification calibration for both TEM and STEM.

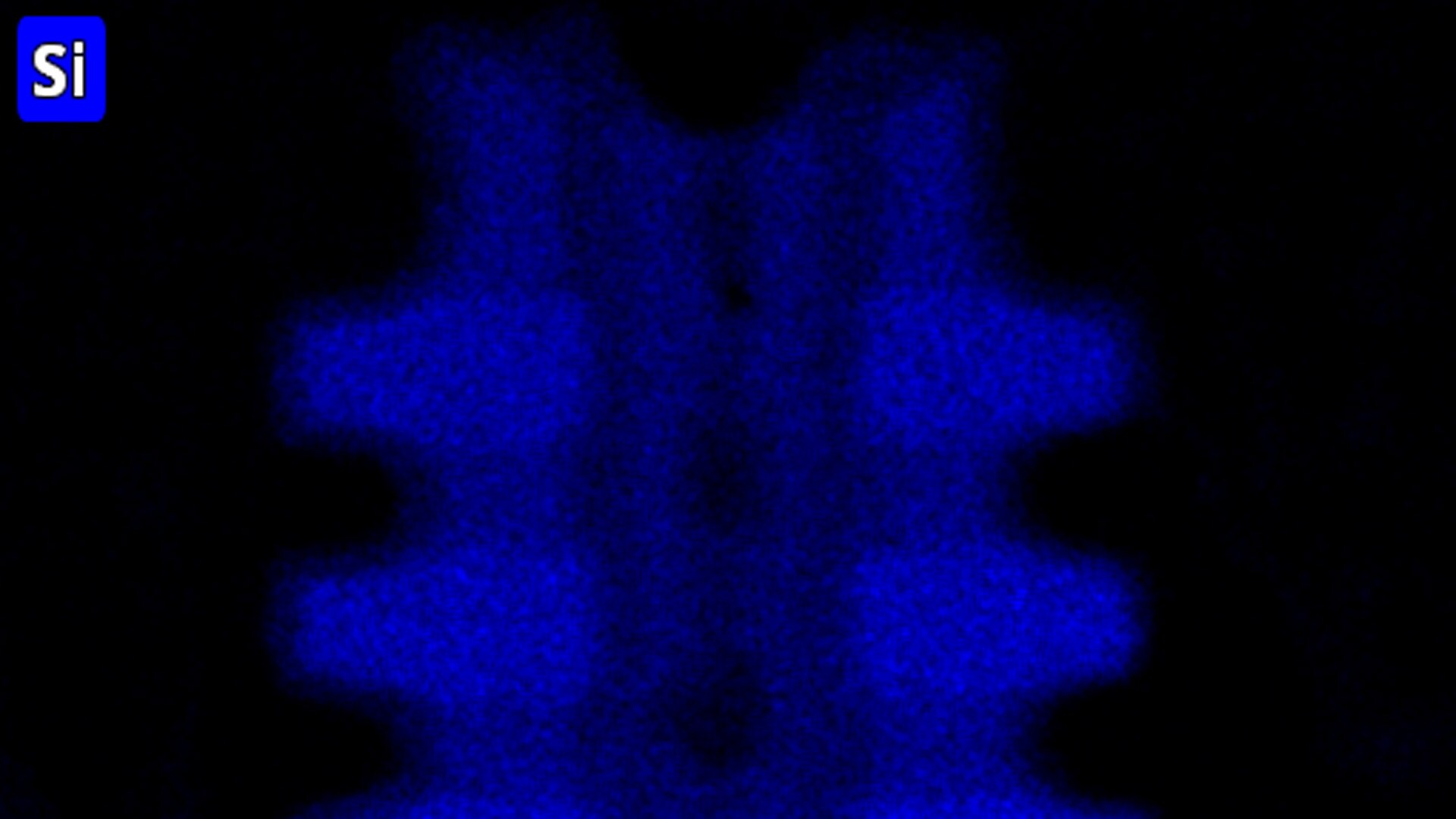

Acquire and quantify EDS data with automation. Use elemental contrast on key critical dimensions to extend STEM.

Critical process data is tracked through sample prep, plucking, and imaging. Metrology can be applied offline to maximize tool acquisition time. All imaging and metrology data is consolidated in a web-based image viewer.

High Tension Range (kV) | 60-200 kV | |

Information Limit 200 kV (nm) | 0.11 | |

Non-corrected | Probe corrected* | |

STEM HAADF Resolution (nm) 200 kV |

|

|

STEM HAADF Resolution (nm) 80 kV |

|

|

Metrology precision on MetroCal wafer for horizontal and vertical |

| |

Electron source |

| |

Ultra-stable electronics and high tension |

| |

Acoustic enclosure |

| |

Constant power lenses |

| |

Piezo stage |

| |

Probe corrector compatible |

| |

Performance, power efficiency, area, and cost are driving packaging innovations. Learn how workflows provide fast, precise, and accurate time-to-data.

Innovation starts with research and development. Learn more about solutions to help you understand innovative structures and materials at the atomic level.

Manufacturing today’s complex semiconductors requires exact process controls. Learn more about advanced metrology and analysis solutions to accelerate yield learnings.

Complex semiconductor device structures result in more places for defects to hide. Learn more about failure analysis solutions to isolate, analyze, and repair defects.

Many factors impact yield, performance, and reliability. Learn more about solutions to characterize physical, structural, and chemical properties.

Semiconductor TEM Imaging and Analysis

Thermo Scientific transmission electron microscopes offer high-resolution imaging and analysis of semiconductor devices, enabling manufacturers to calibrate toolsets, diagnose failure mechanisms, and optimize overall process yields.

TEM Metrology

Advanced and automated TEM metrology routines deliver significantly greater precision than manual methods. This allows users to generate large amounts of statistically relevant data, with sub-angstrom-level specificity, that is free of operator bias.

Semiconductor TEM Imaging and Analysis

Thermo Scientific transmission electron microscopes offer high-resolution imaging and analysis of semiconductor devices, enabling manufacturers to calibrate toolsets, diagnose failure mechanisms, and optimize overall process yields.

TEM Metrology

Advanced and automated TEM metrology routines deliver significantly greater precision than manual methods. This allows users to generate large amounts of statistically relevant data, with sub-angstrom-level specificity, that is free of operator bias.

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.