Search Thermo Fisher Scientific

- Order Status

- Quick Order

-

Don't have an account ? Create Account

Search Thermo Fisher Scientific

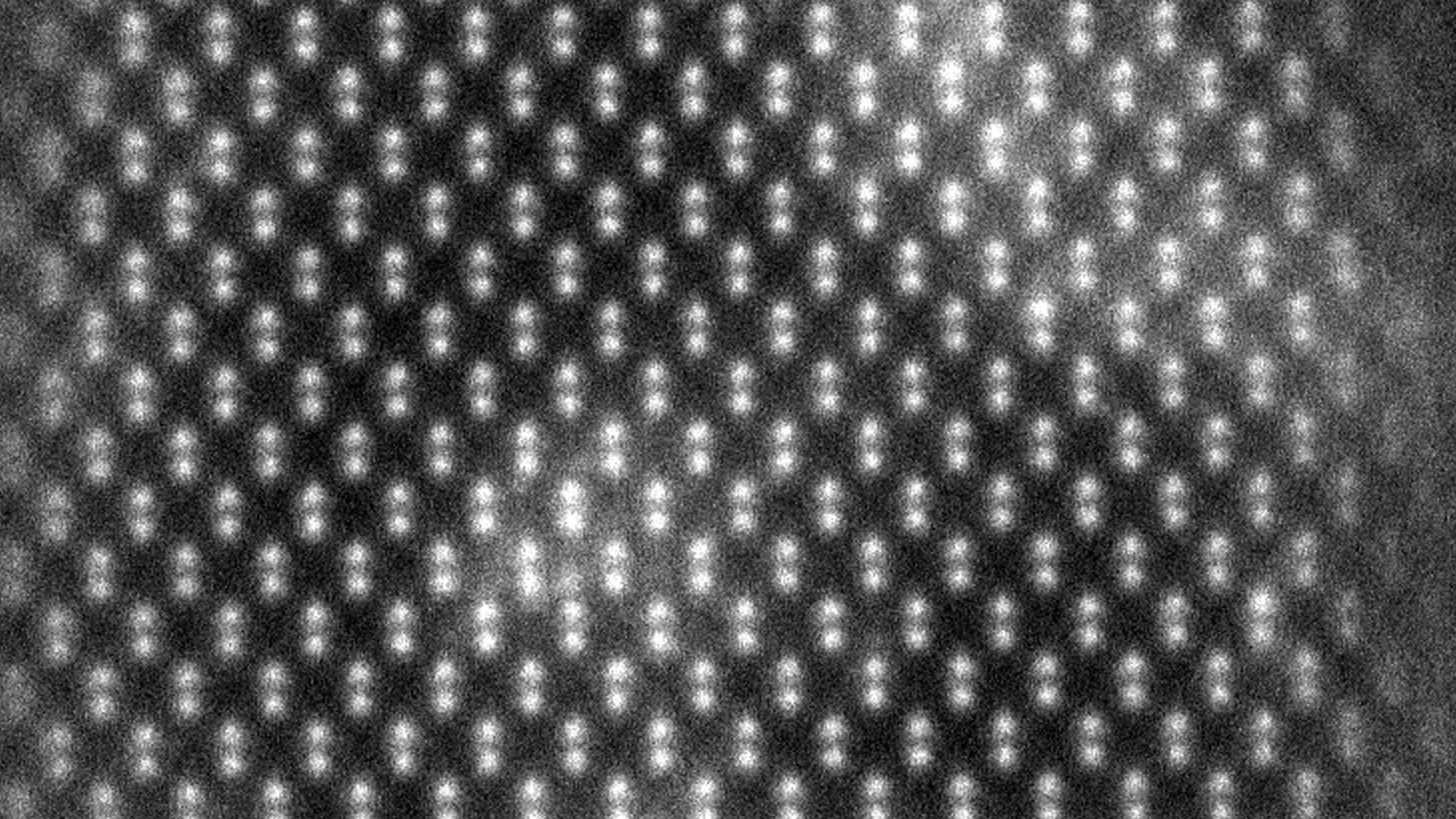

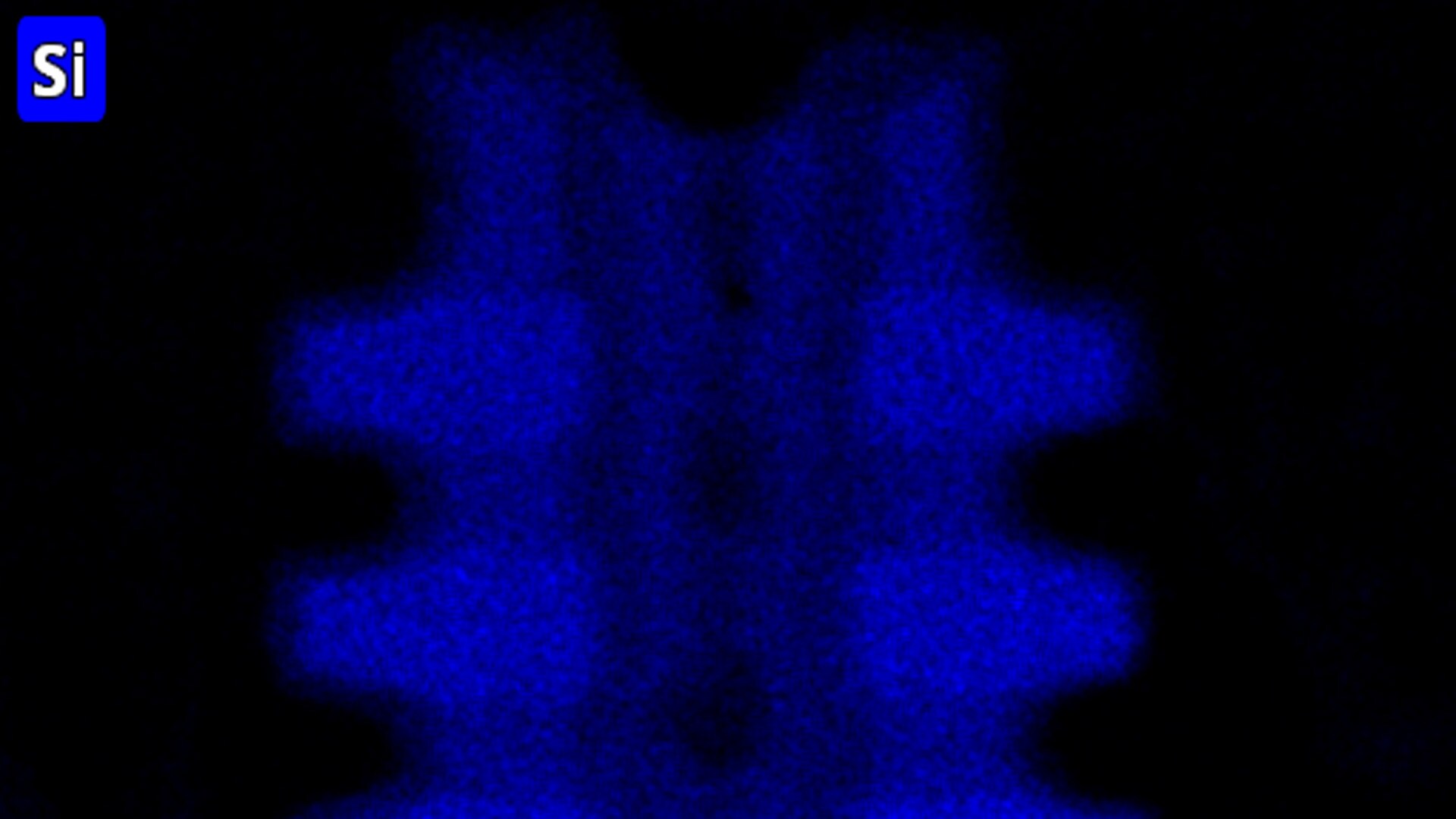

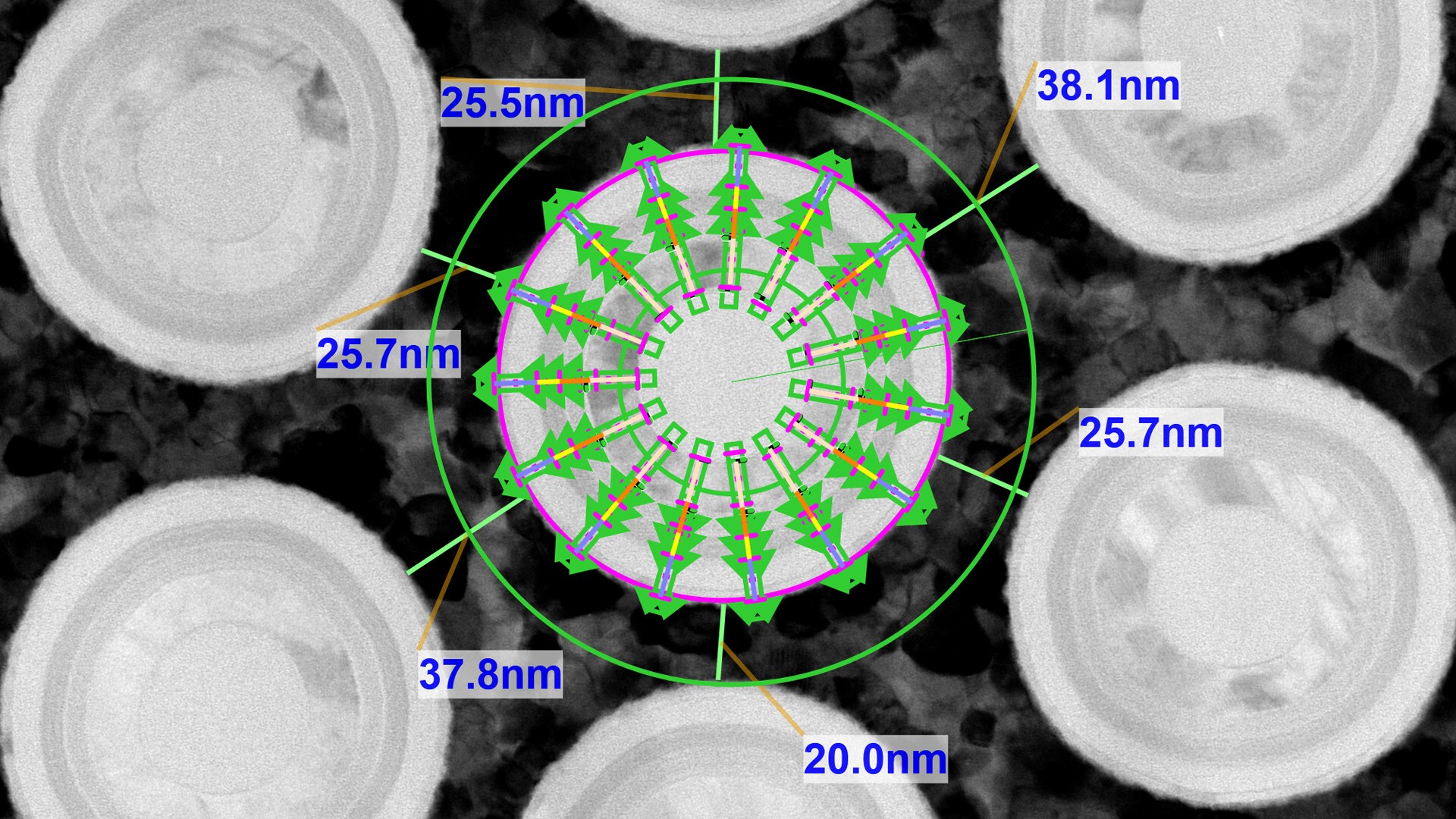

Semiconductor devices are becoming more complex due to the demand for faster speeds, shorter time-to-yield, and time-to-market. Scanning transmission electron microscopy (S)TEM metrology has become a necessary element of all leading-edge wafer fabrication workflows, since highly specific measurements are needed to generate statistically relevant data with sub-angstrom accuracy. This data allows manufacturers to calibrate toolsets, diagnose failure mechanisms, and optimize overall process yield.

Thermo Fisher Scientific offers metrology workflows that are flexible enough to enable manual, semi-automated, or even fully automated solutions, depending on your needs. The Thermo Scientific Metrios AX System is the first TEM designed to provide the fast, precise measurements that semiconductor manufacturers need to develop and control their wafer fabrication processes. Learn more by visiting the Metrios product page below.

Innovation starts with research and development. Learn more about solutions to help you understand innovative structures and materials at the atomic level.

Many factors impact yield, performance, and reliability. Learn more about solutions to characterize physical, structural, and chemical properties.

Manufacturing today’s complex semiconductors requires exact process controls. Learn more about advanced metrology and analysis solutions to accelerate yield learnings.

As semiconductor devices shrink and become more complex, new designs and structures are needed. High-productivity 3D analysis workflows can shorten device development time, maximize yield, and ensure that devices meet the future needs of the industry.

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.