Search Thermo Fisher Scientific

- Contact Us

- Quick Order

-

Don't have an account ? Create Account

Search Thermo Fisher Scientific

Filters are commonplace in today’s society, and fulfill critical functions in industry and the household, ranging from air filters that give you clean, breathable air to water filters that ensure you have safe, potable tap water.

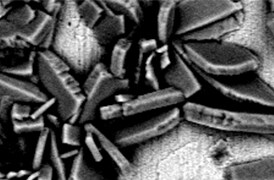

The key to high-performance filtration is the development of synthetic fibers. To optimize a filter’s design (so it continues to filter a broad range of dry or wet particulates over time), features like fiber diameter, density, and surface morphology all need to be thoroughly characterized and optimized.

Traditional methods for fiber analysis, such as optical microscopy and atomic force microscopy (AFM), are insufficient for this multi-modal analysis. Optical microscopy lacks the resolution necessary to accurately study nanofibers, whereas AFM is too slow and suffers from physical probe issues. These methods also rely on slow, manual measurement and data analysis.

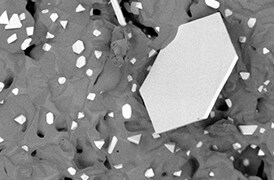

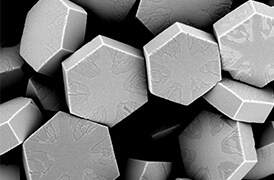

Scanning electron microscopy (SEM), meanwhile, offers exceptional resolution capabilities, and allows you to automatically characterize multiple fibers at the same time. With the addition of leading automation software, critical filter parameters can be extracted rapidly and reliably. This minimizes the time spent using SEM in the lab, increasing development throughput as you can quickly and easily analyze fibers for filtration design.

Thermo Fisher Scientific offers a range of SEM instrumentation for fiber analysis. When combined with Thermo Scientific FiberMetric Software, accurate, automated measurement of micro- and nanofiber properties is possible.

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.