Search Thermo Fisher Scientific

Manufacturing & Processing Learning Center

Manufacturing & processing learning center features

On demand webinar

Learn about the basics of characterizing battery materials and the special equipment required to run these tests, including the basics of testing battery materials and exemplary case studies.

Webinar series

Sign up for one of our on-demand webinars to learn how infrared and Raman spectroscopy can help you reveal the mysteries of your polymers—from research and failure analysis to quality control and beyond.

On demand webinars

Learn how the Raman, NIR and XRF portable devices can improve pharma manufacturing processes from raw material inspection through final biologic product identification.

eBook

Download our free eBook to learn about Thermo Scientific products that improve each stage of the steel manufacturing production process.

eBook

Learn how to improve product quality, boost efficiency, lower productions costs, and create safer, cleaner cement production lines.

eBook

Do you know how to choose a gauging platform, sensor, and scanner that will work best for your application? Download the free eBook to learn more.

Video

The Thermo Scientific Nicolet iS50 FTIR spectrometer, with automated optical configurations and multiple sampling stations, is the ultimate materials analysis workstation for the entire polymer supply chain, from raw pellets to finished goods.

Video

SampleArray automation assembles user-defined tube rack configurations at room temperature or -20°C and can be used with a range of systems.

Video

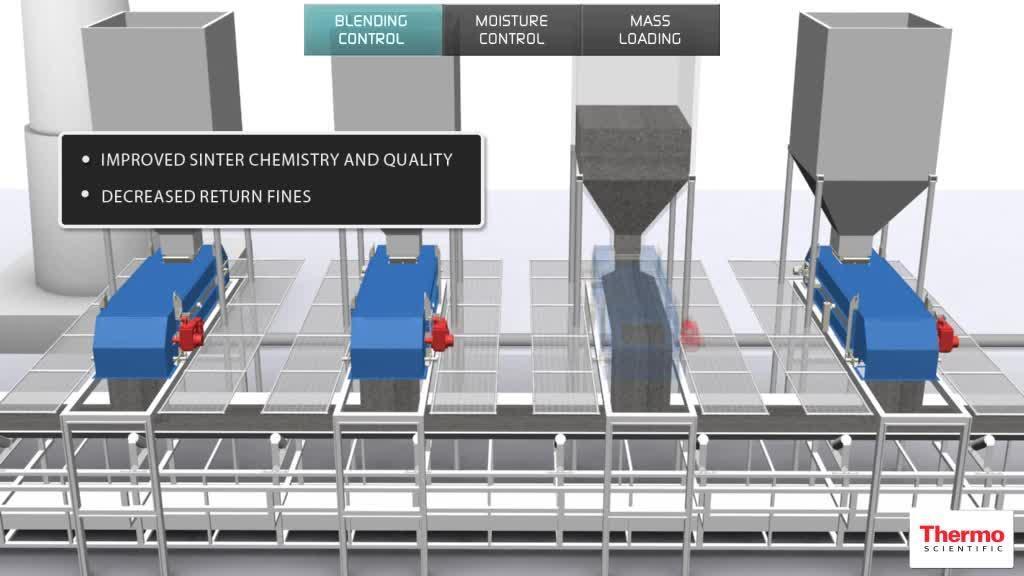

Thermo Fisher Scientific offers advanced systems and equipment for all aspects of iron and steel manufacturing, particularly for measuring and controlling sintering process fluctuations.

Infographic

Contaminated scrap metal can result in expensive plant decontamination and shut down. Multiple points of inspection are needed to ensure processed materials are free from radiation.

Infographic

Learn about our complete range of technologies that improve each stage of the steel manufacturing production process, from incoming raw materials to the final coating line.

Infographic

Learn about our instruments, equipment and software to help cement producers improve product quality, boost efficiency, and lower productions costs.

eBook

This eBook offers guidance and best practices for the issues that concern the pharma and biotech manufacturing industry the most.

Blog post

There have been reports from the U. S. Food and Drug Administration that certain foods and beverages, particularly fruit juices, contain high levels of phthalates. In some cases, deliberate adulteration of soft drinks with phthalate esters has been reported, thus the need for an analytical procedure for quantitative analysis of phthalate esters.

Application note

The metallurgical industry is one of the biggest users of gamma ray sensors for inventory, process control, and quality assurance. Learn the basic theory of gamma transmission gauging techniques found useful in mining, milling, and metal production for level and density measurement applications.

Manufacturing & processing learning center subtopics

Pharmaceutical Manufacturing Processes and Production Information

Learn about solutions to improve manufacturing processes, save time, improve processes, protect brand integrity, and help ensure patient safety in the pharmaceutical and biotechnology industries.

Cement Analysis and Production Information

Learn about the five stages of cement production and the steps to maintain consistent raw material quality with minimal chemistry deviation, from quarry to silo to customer.

Steel Manufacturing Information

Improve each stage of the steel production process with solutions for raw material quality control, process optimization, laboratory analysis, detecting potentially contaminated scrap metal, and air quality monitoring.

Automotive Information

From leather interiors to an alternative energy powertrain, every component in today's automobile is designed for profitability, performance and appeal. Analytical instrumentation that reveals the chemistry and composition of materials plays an essential role across the supply chain, from R&D to failure analysis.

Chemicals Information

From streamlining workflows to minimizing quality assurance errors, we offer easy-to-implement solutions with a comprehensive portfolio of equipment, software, services and resources.

Electronics Information

From raw material testing, process monitoring, failure analysis, and QA testing.

Polymers and Plastics Information

Accurate polymer identity verification can be critical. Polymer manufacturers need to create new materials and deliver high quality to meet ever changing end-use requirements. A thorough, precise testing and analysis process is mandatory to ensure quality and stay competitive in today’s environment.

Power & Energy Information

Petrochemical analysis can be challenging due to difficult matrices, a wide range of contaminants, and sensitivity requirements. We offer a range of products including Ion Chromatography (IC), Gas Chromatography (GC), GC-MS and ICP; which will enhance your analytical capabilities and improve your processes.

Manufacturing and Processing Resource Library

Access a targeted collection of scientific application notes, case studies, videos, webinars and white papers for chemical, electronic, power and energy, plastics and polymers, and paints and pigments analysis.