Search Thermo Fisher Scientific

Minerals Mining and Processing

Follow and respond to process trends in real time

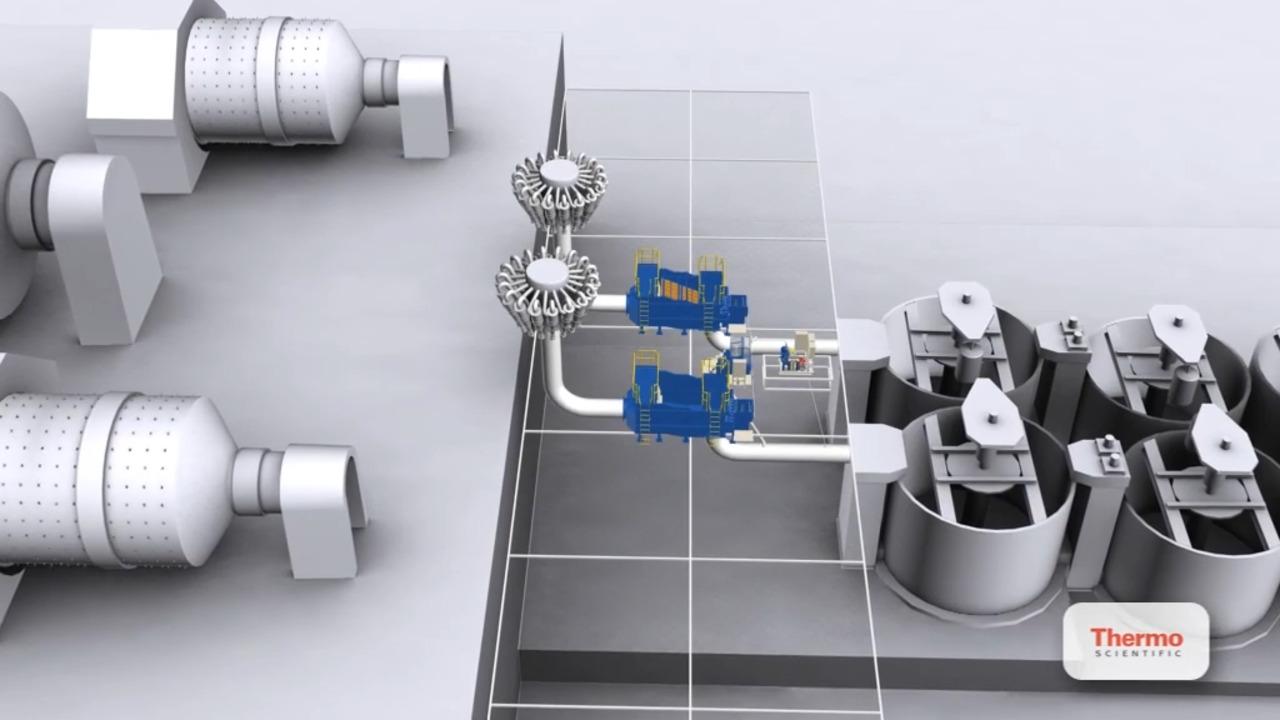

Improve recovery, lower costs, and achieve environmental compliance in the slurry process control system with Thermo Scientific metallurgical equipment and sampling systems. Thermo Scientific metallurgical sample preparation equipment supplies companies with reliable, accurate data and critical input for metallurgical accounting and particle size analysis. This allows operators to optimize their process, realize significant savings, and improve profitability. Our analysis and metallurgical sampling systems can be configured for all plant sizes to meet technical constraints and provide the lowest total cost of ownership.

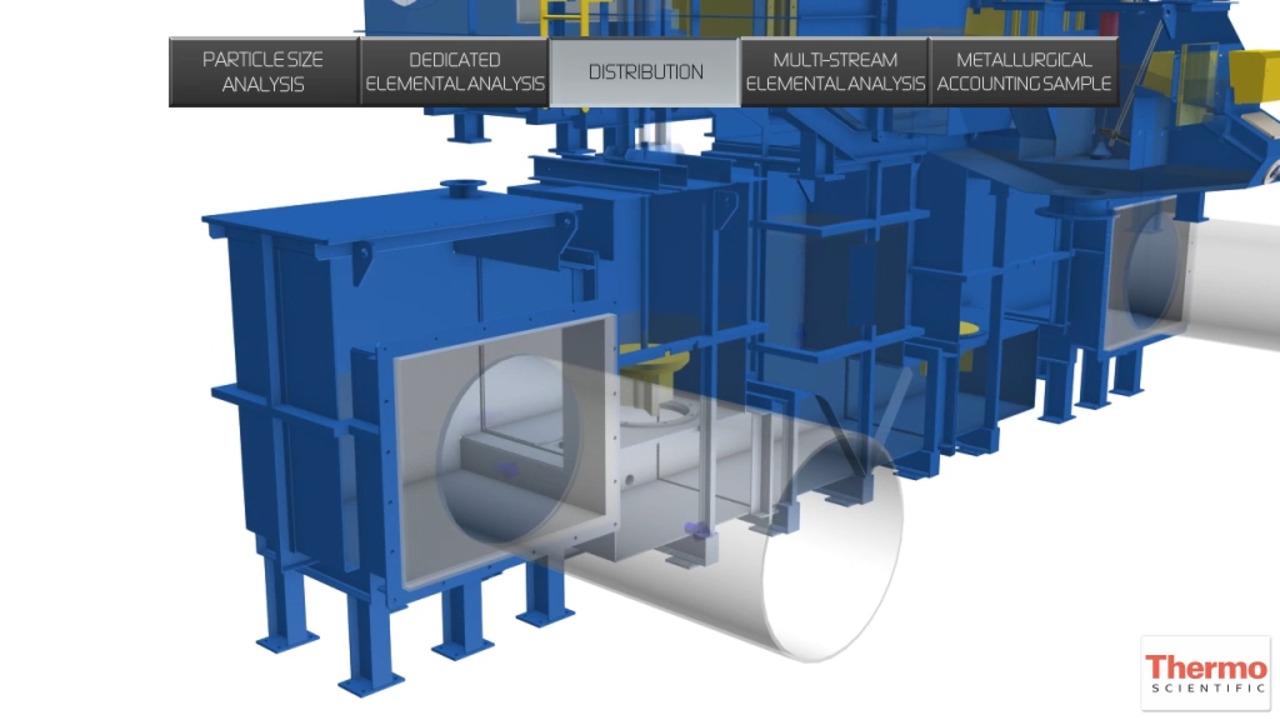

The Thermo Scientific AnStat-330 Online Sampling and Elemental Analysis Station provides composite metallurgical samples for accounting while providing online elemental analysis.

The Thermo Scientific MEP-300 Multi-Element Probe has been developed to replace both MEP and MEP-200 liquid nitrogen cooled XRF immersion probes used in the AnStat and MSA X-ray analyzer products.

The Thermo Scientific GS Omni Analyzer provides accurate, real-time elemental analysis of multiple slurry process streams for both light and heavy elements.

The Thermo Scientific Gravity Feed Sampler is a simple, cost-effective alternative for producing a sample for a multi-stream analyzer.

The Thermo Scientific Pressure Pipe Sampler is a simple, cost-effective alternative to produce a sample for a multi-stream analyzer.

The Thermo Scientific MSA multi-stream analyzer provides accurate, cost-effective elemental analysis of up to 12 slurry streams.

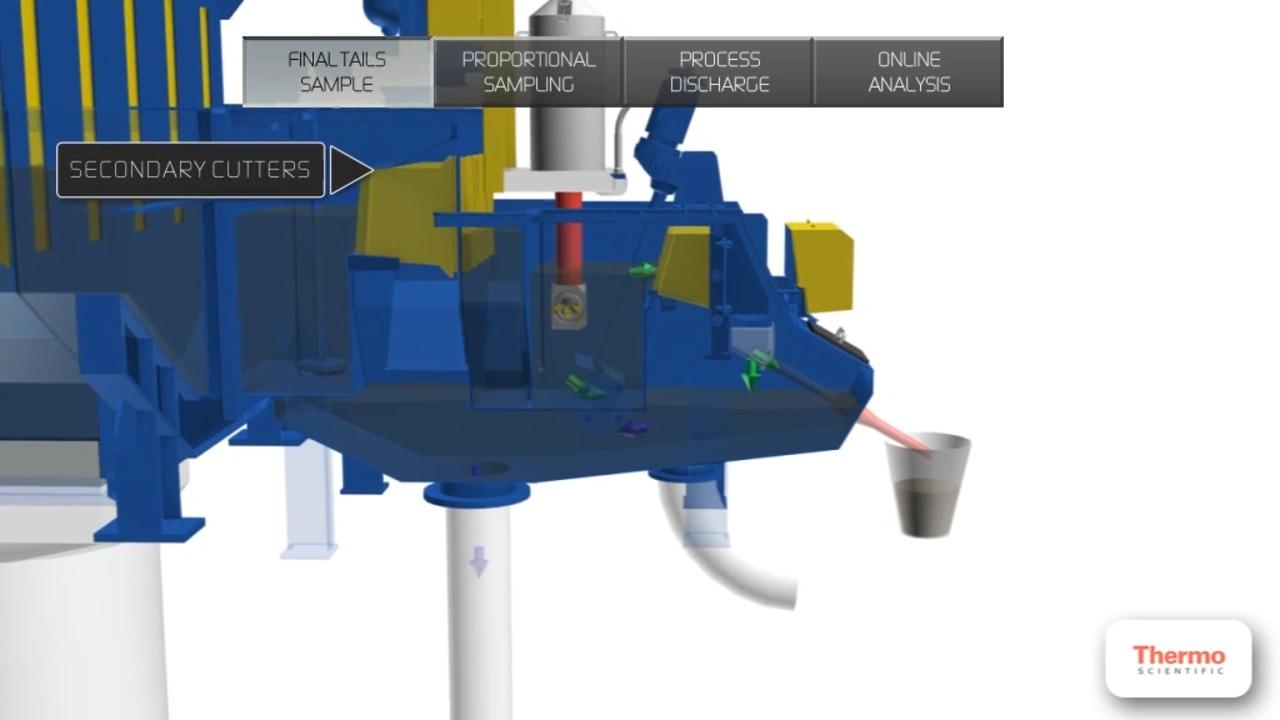

The Thermo Scientific SamStat-30 provides periodic composite samples of a full slurry stream for metallurgical accounting.

The Thermo Scientific Particle Size Analyzer PSM-500 provides accurate feedback to optimize grinding circuit performance, enhancing mineral recovery and quality and improving energy efficiency.

From mineral analysis to complete bulk weighing monitoring and sampling systems to informatics, discover the latest equipment and technology to help optimize your mining operations, and keep coal, cement, or mineral processing operations running efficiently, safely, and profitably.

From mineral analysis to complete bulk weighing monitoring and sampling systems to informatics, enter the Mining Toolkit App and find the latest equipment and technology for your mining operations!

Benefits of the in-stream analysis system

In-stream analysis (ISA) systems provide continuous on-line analysis of metals and density in slurry streams around the flotation process. This information allows plant operators or a process control system to fine-tune and optimize the process much quicker after normal disturbances caused by variations in feed-rates, pulp density, grinding, head-grade, and mineralogy. Adjustments to pulp levels, aeration rates, reagent flow-rates, etc. can then be made to continuously maximize the recovery while maintaining the concentrate grades within the required specification.

Further benefit is derived from continuous, dedicated on-line elemental analysis by providing real-time indication of unplanned process upsets. Operators can react to such upsets immediately minimizing metal loses due to failure of reagent feeders or flotation cell level control valves or excessive recovery of gangue leading to high circulating loads in the cleaner circuit. The net result is a reduction in duration and magnitude of loss producing events in the minerals beneficiation operation leading to significant economic gains in terms of additional concentrate produced.

ISA systems are rugged, reliable, and requires minimal maintenance. Economic benefits include:

- Increases in recovery.

- Decreases in reagent consumption.

- Improved and/or more consistent concentrate grades.

- Reductions in man-power requirements.

- Greater efficiency of experimentation and innovation.

PGNAA provides iron ore beneficiation plant control

Prompt gamma neutron activation analysis (PGNAA) technology provides elemental analysis in the iron ore industry on both bulk materials and slurries. Used for process control in the coal and cement industries for decades, PGNAA technology has proven to be a successful measurement technique within iron ore beneficiation plants to help treat challenging ore types, improve efficiency and product quality, and control and stabilize the process.

The GS-Omni, a multi-stream PGNAA analyzer, provides real-time slurry elemental analysis of feed, concentrate, and tails streams within the processing plant. The analytical data from the analyzer can be exploited with a control strategy to correct and stabilize the plant on a much shorter time scale compared to lab analysis of control or composite samples, delivering significant economic benefits and greater operational flexibility. The economic benefits include more stable product quality, a reduction in reagent consumption, composite sampling and laboratory costs.

A critical requirement of any PGNAA analyzer design is to ensure uniformity of measurement across the volume of material passing through the analyzer. This ensures that every portion of the sample passing through the analyzer has an equal probability of being measured, which is consistent with sampling theory. A well-designed PGNAA slurry analyzer can essentially eliminate sampling and sample preparation errors associated with the material being analyzed, which are a limiting factor of the total error associated with laboratory assays or other online measurement techniques.

To learn more, visit the PGNAA and PFTNA Technology Page.

The Thermo Scientific Ramsey Series 14 Precision Belt Scale System is specifically designed for high accuracy or basis-of-payment applications requiring certification by government and regulatory agencies.

Related density measurement products

Accurately measure the density or percent solids of a liquid or slurry in a pipe for any application with the Thermo Scientific DDG3 Digital Density Gauge. Now with latest controller and communications protocols options, this non-intrusive, non-contact nuclear density gauge is suitable for applications containing a high temperature, highly toxic or highly corrosive process.

Related electron microscopy products in minerals and mining

Thermo Scientific Electron Microscopy automated mineralogy workflows are transforming productivity for mining customers by delivering relevant answers when, where, and how they are needed. With Electron Microscopy, customers accelerate analysis, reduce analysis costs, and increase throughput to more easily make critical characterization and production decisions.

Belt conveyer scales are an important part of a mining operation’s bulk material handling system. A belt scale system monitors production output and inventory, or regulates product loadout, while providing vital information for the effective management and efficient operation of your business. There are many options to consider when selecting a belt scale system. How do you know which one is right for your application?

Check out the Belt Scale Selection Guide