Search Thermo Fisher Scientific

Steel Manufacturing Information

Improve each stage of the steel production process

The iron and steel manufacturing process encompasses many applications to produce clean and ultraclean steel with improved mechanical properties that meets customer requirements. We have solutions for raw material quality control, process optimization, laboratory analysis, detecting potentially contaminated scrap metal, and air quality monitoring, all of which are needed to produce quality strip in a manner that maximizes mill yield and minimizes scrap while meeting specifications for thickness, width, hardness, and strength.

Steel manufacturing information features:

White Paper

High Speed Archiving of Thickness and Profile Data in the Hot Strip Mill

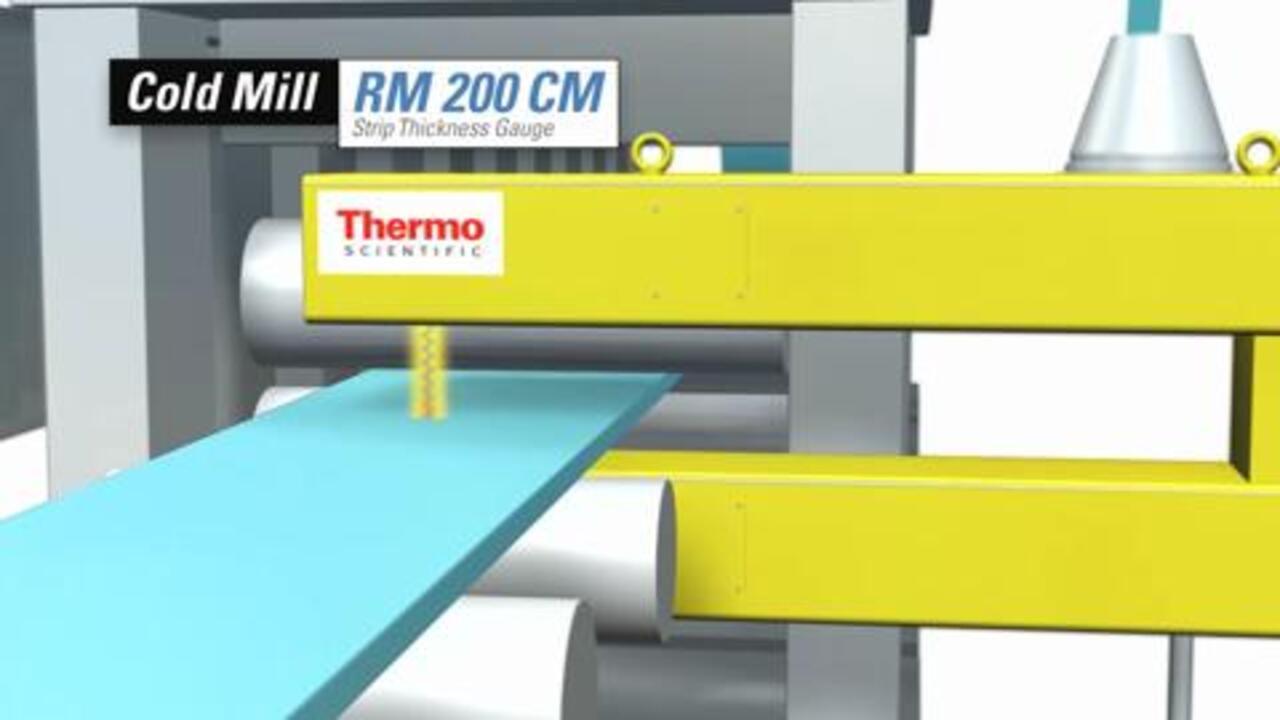

This paper describes a stereoscopic x-ray profile gauge with the ability to determine both the cross-thickness profile and the physical position of the strip in space.

Infographic

The Iron and Steel Manufacturing Process

View this process map of the complete range of technologies that improve each stage of the steel manufacturing production process, from incoming raw materials to the final coating line.

Application Note

Brochure

Optimize Your Metals Production Process

Shifts in steel production require producers to be aware of, and willing to adopt, the latest technologies to lead the industry, both commercially and environmentally.

Application Note

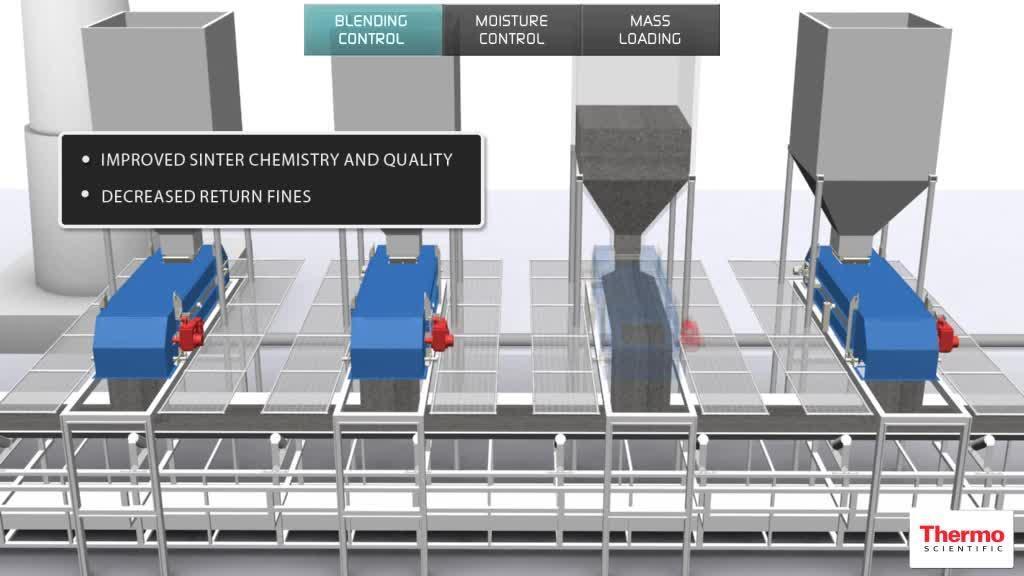

Application of On-line Elemental Analysis for Control of Sinter Feed Basicity

The basicity of sinter feed material is an important parameter in the efficient operation of the sintering and iron making process.

Infographic

10 Reasons (and Places) Recyclers Need Radiation Detection

Contaminated scrap metal can result in expensive plant decontamination and shut down. Multiple points of inspection are needed to ensure processed materials are free from radiation.

eBook

A Practical Guide to Improving Steel Manufacturing Processes and Production Methods

Download our free eBook to learn about Thermo Scientific products that improve each stage of the steel manufacturing production process.

Video

The Iron Ore Sintering Process

The production of high-quality sinter is crucial for assuring consistent, stable furnace productivity with a low consumption of reductants.

Video

Hot and Cold Rolling Processes in Steel Manufacturing

Metal thickness and coating weight gauges provide precise, real-time measurements during high-speed production of steel plate and sheet.

Poster

Ultra-Fast Inclusion Analysis with Spark-OES

Spark OES for the analysis of solid steel samples allows performing various types of inclusion related determinations in the time of a standard OES analysis.

The CB Omni analyzer uses Prompt Gamma Neutron Activation Analysis (PGNAA) or Pulsed Fast Thermal Neutron Activation (PFTNA) to determine elemental concentration in bulk materials. The method is deeply penetrative and measures through many centimeters of material making it an ideal technology for real-time elemental analysis of bulk materials on conveyor belts.

To learn more about PGNAA and PFTNA, visit the PGNAA and PFTNA Technology page.