Search Thermo Fisher Scientific

Pharmaceutical QA/QC Information

Your pharmaceutical quality is assured

Modern advances in pharmacology have resulted in increased life expectancy and reduced suffering of patients fighting disease. It is the frail and vulnerable that have come to rely on modern medicines. Consequently, it is paramount that prescribed drugs have the desired therapeutic efficacy, without fear of harmful side effects from impurities. For healthcare systems to provide quality care, prescription medicines must meet regulatory quality assurance standards.

Featured ebook

Increasingly pharmaceutical manufacturers are looking to data management and informatics solutions to ensure that critical information is not only accessible when demanded, but ready to provide decision support to the highest levels of the organization.

Featured Compendium

Pharmaceutical Analysis Applications Compendium

Stay at the cutting edge of pharma applications with the analysis of a range of molecules which are present as counter ions, impurities, degradants and related substances and diastereomers.

Pharmaceutical QA/QC information subtopics

Counter Ion Analysis Information

Salt formation is important in pharmaceutical and biopharmaceutical drug development to improve physicochemical properties of the drug. Approximately half of all drugs are formulated and administered as salts. A broad selection of inorganic and organic ions can be used as pharmaceutical counterions.

Extractables and Leachables Information

Extractable and Leachable compounds can migrate from polymeric materials used in container closure, production, and packaging systems for pharmaceuticals and biopharmaceuticals. A container closure system should not release chemicals that can accumulate in the drug product in quantities sufficient to present a risk of toxicity or affect its stability or efficacy.

Impurity Analysis Information

Organic synthesis or cell culture (in the case of biotherapeutics) often leads to less than 100% production. Consequently, a range of impurities are made together with any medicine. In addition, impurities can come from anything within the production or packaging chain that the medicine comes into contact with.

Residual Solvent Analysis Information

Residual solvents in pharmaceuticals are volatile organic compounds used or created during the manufacture of drugs and pharmaceutical additives. The U.S. Pharmacopeia (USP) general chapters <467> Residual Solvents were created based on the analytical methods specified in the EP (European Pharmacopoeia) to ensure pharmaceuticals are free from toxicologically significant levels of volatile organic compounds.

Elemental Impurities Information

Elemental impurities in pharmaceutical formulations can come from catalysts, formulation ingredients and from process vessels. They can interfere with drug effiicacy or elicit a direct toxic effect on the patient.

Featured webinars

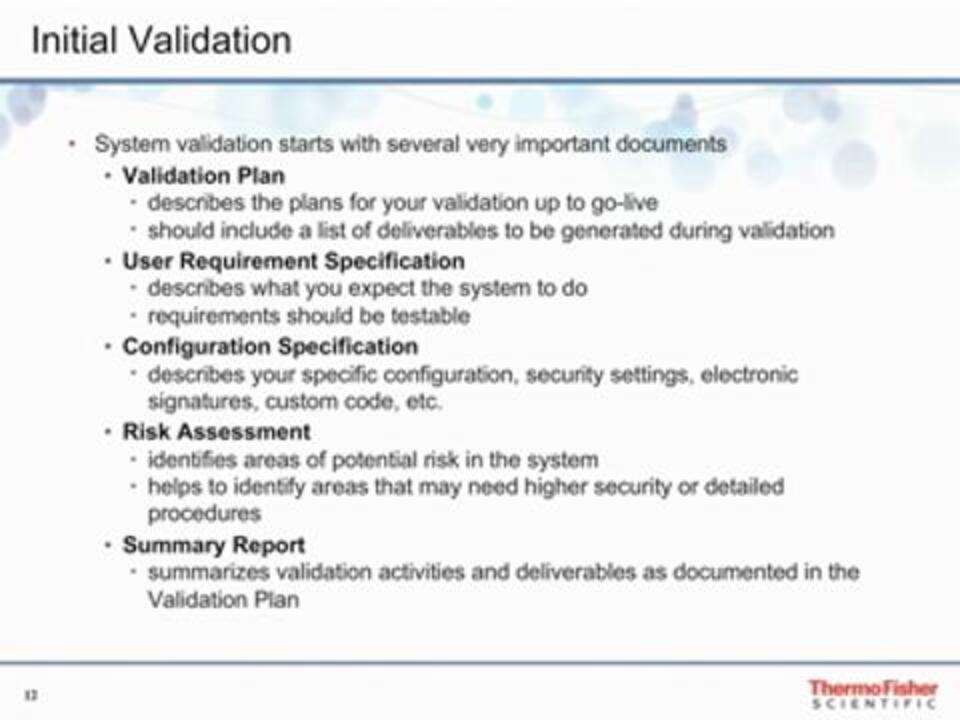

Understand necessary steps to have a successful, cost-effective software validation, including challenges and pitfalls, as well as potential solutions.

By law, pharmaceutical manufacturers must identify and verify all incoming materials. Current Good Manufacturing Processes (cGMP) require that not only incoming raw materials but all in-process materials be tested for identity, strength, quality, and purity throughout the manufacturing process.

Make sure your QA/QC program is compliant. Download the free eBook, What You Need to Know About Field-Based Material Identification and Authentication for Pharmaceuticals.

Save time, improve processes, protect brand integrity, and ensure patient safety, from raw material identification through the pharmaceutical manufacturing process, to finished and packaged pharmaceutical product inspection.

Lab ideas for people – like yourself– in analytical labs making medicines, directed by topics, ideas and thoughts from your fellow medicine makers. Each month, a new theme addresses challenges and solutions around technology and workflows.