Search Thermo Fisher Scientific

Cellular and Stem Cell Bioprocessing Information

Overcome the inherent challenges of cell therapy production

Challenges in the production of cellular therapies are many, including safe navigation in a dynamic regulatory landscape, quality and consistency of processes, and safety and productivity, all in a cost-effective manner. Whether allogenic or autologous in nature, your cells require impeccable processing. That’s where we come in. From cell preparation and cell growth to cell expansion, cell harvest and storage, to transport, we are with you at every step of the way.

Impermeability of PETG Bottles to Hydrogen Peroxide Sterilants

Hydrogen peroxide (H2O2) is a highly effective antimicrobial agent. Due to this property, and its availability and relatively low cost, it is commonly used as a sterilant in many areas where microbial contamination must be reduced or eliminated.

Seal Integrity of Thermo Scientific Nalgene InVitro Biotainer Closures

Seal integrity of a container is critical to prevent loss of contents or contamination from outside sources. Since plastic is a malleable material, forces borne at the thread and mating surfaces of the closure of a plastic container can deform the material over time or under certain environmental conditions.

Baseline Data to Support your Validation Requirements

The qualification and validation of production, harvest and containment supplies is an integral part of any Biopharmaceutical application process. Regulatory guidelines around the World recommend that the production, storage and packaging components be assessed for extractables or leachables that may interact with or impact the product being manufactured.

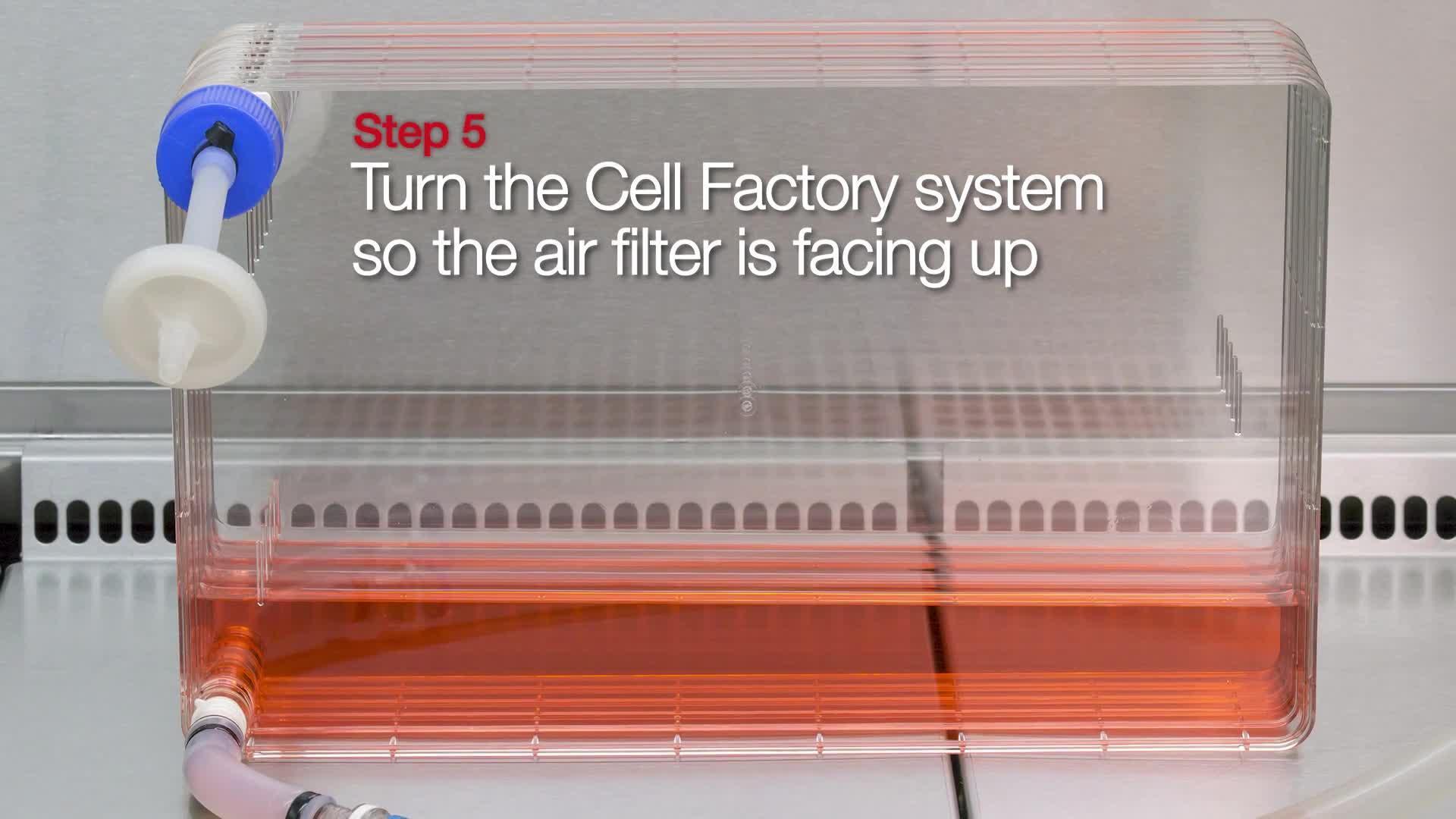

Cellular and stem cell information videos

See how Thermo Scientific customized fluid transfer systems can simplify adherent cell culture production.

Bioprocessing Resource Library

Access a targeted collection of scientific application notes, case studies, videos, webinars, and white papers for bioproduction.

Bioprocessing resources

Access a targeted collection of scientific application notes, case studies, posters, white papers and more for bioprocessing: