Search Thermo Fisher Scientific

Materials Science

Nanoscale Prototyping

Nano prototyping FIB-SEM tools that accelerate your research and development.

As technology continues to miniaturize, the demand for nanoscale devices and structures is ever increasing. The challenge of converting the latest ideas and designs into valuable assets only continues to grow, and significant technical and financial barriers need to be overcome for successful prototyping of nanoscale devices.

Standard nanofabrication batch processes involve the combined use of different machines for each pattern layer. These instruments might include a spin coater for resist application, a lithography tool, wet chemistry for resist development, a plasma cleaner, and deposition or etching equipment for pattern transfer. The use of so many distinct tools results in a costly and time-consuming prototyping process. As researchers push nanotechnology towards smaller dimensions, these established procedures and recipes often no longer keep pace with the demands of rapid development.

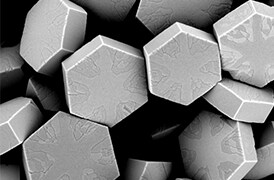

A reliable nanoprototyping technique would feature dedicated strategies for the execution of pattern designs. This would include the ability to observe the patterning process live and to immediately image the resulting structures with high resolution, offering unique control over the patterning process. This would also provide an immediate feedback loop for the observer, accelerating their development process. This is why DualBeam (focused ion beam – scanning electron microscopy, or FIB-SEM) technology is ideally suited for nanoprototyping applications. The SEM provides high-resolution imaging as the FIB accurately adds or removes material at the nanometer scale via milling or chemical deposition.

Thermo Fisher Scientific offers a smart and efficient way of turning nanoscale designs into reality. Our DualBeam instruments feature unique precision stages and are combined with state-of-the-art software and patterning engines. Together, these produce a robust prototyping workflow that enables you to quickly design, create, and inspect micro- and nanoscale functional prototype devices.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Battery Research

Battery development is enabled by multi-scale analysis with microCT, SEM and TEM, Raman spectroscopy, XPS, and digital 3D visualization and analysis. Learn how this approach provides the structural and chemical information needed to build better batteries.

Metals Research

Effective production of metals requires precise control of inclusions and precipitates. Our automated tools can perform a variety of tasks critical for metal analysis including; nanoparticle counting, EDS chemical analysis and TEM sample preparation.

Catalysis Research

Catalysts are critical for a majority of modern industrial processes. Their efficiency depends on the microscopic composition and morphology of the catalytic particles; EM with EDS is ideally suited for studying these properties.

Nanoparticles

Materials have fundamentally different properties at the nanoscale than at the macroscale. To study them, S/TEM instrumentation can be combined with energy dispersive X-ray spectroscopy to obtain nanometer, or even sub-nanometer, resolution data.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.