Search Thermo Fisher Scientific

FIB-SEM MICROSCOPES

FIB-SEM and Laser Ablation

Combined focused ion beam milling and laser ablation tools.

Join the Conversation

Focused ion beam milling and femtosecond laser ablation

Thermo Scientific Helios 5 PFIB Laser Systems combine plasma focused ion beam milling with femtosecond laser ablation and SEM (scanning electron microscopy) imaging. This “TriBeam” combination enables high-resolution imaging and analysis with in situ ablation capability, offering unprecedented material removal rates for fast millimeter-scale characterization at nanometer resolution.

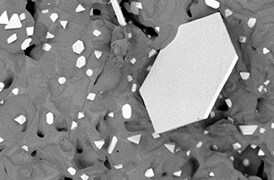

The femtosecond laser can cut many materials at rates that are orders of magnitude faster than a typical FIB. A large cross-section (hundreds of micrometers) can be created in less than five minutes. Because the laser has a different removal mechanism (ablation versus the ion sputtering of FIB), it can easily process challenging materials, such as non-conductive or ion-beam-sensitive samples.

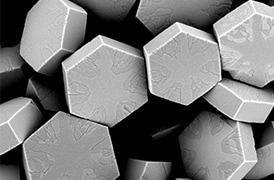

The extremely short duration of the femtosecond laser pulses introduces almost no artifacts such as heat impact, microcracking, melting, or those typical of traditional mechanical polishing. In most cases, the laser-milled surfaces are clean enough for direct SEM imaging and even for surface-sensitive techniques such as electron backscatter diffraction (EBSD) mapping.

We offer a broad product portfolio and advanced automation capabilities for applications such as transmission electron microscopy (TEM) sample preparation, atom probe tomography (APT) sample preparation, and 3D structural analysis.

Transmission electron microscopy and atom probe tomography sample preparation

Built on the proven Helios 5 DualBeam platform, these instruments incorporate a suite of state-of-the-art technologies to provide high-performance, high-resolution transmission electron microscopy (TEM) and atom probe tomography (APT) sample preparation and extremely high-resolution SEM imaging with precise materials contrast.

3D Structural analysis

When combined with Thermo Scientific Auto Slice & View Software, TriBeam instruments provide 3D insight into sample structure by selectively removing (milling) the material for subsurface characterization. Digital reconstruction generates multi-modal 3D datasets that can consist of a variety of signals, including backscattered electron (BSE) imaging for maximum materials contrast, energy dispersive spectroscopy (EDS) for compositional information, and electron backscatter diffraction (EBSD) for microstructural and crystallographic information. The SEM capability of TriBeam instruments offers nanoscale details across a wide range of working conditions, from structural information obtained at 30 keV in STEM mode to charge-free, detailed surface information at lower energies. With unique in-lens detectors, TriBeam systems are designed for simultaneous acquisition of angular/energy-selective secondary-electron and BSE data. Fast, accurate, and reproducible results are provided by our unique SEM column design, which features fully automated lens alignments.

Helios 5 Laser FIB-SEM Product Family

Thermo Fisher Scientific offers a broad range of (P)FIB-SEM systems with fully integrated femtosecond lasers. This TriBeam product family consists of three models, all featuring the best-in-class Thermo Scientific Elstar SEM Column, a high-precision 150 mm piezo stage, and a large chamber. The main difference between these models is the FIB column:

- Helios 5 Laser System comes with high-throughput Tomahawk HT FIB

- Helios 5 Laser PFIB System has a high-performance Xe+ PFIB column

- Helios 5 Laser Hydra System is a unique solution featuring multi-ion species PFIB technology

15,000x faster rate of material removal via laser

Millimeter-scale cross sections with up to 15,000x faster material removal than a typical focused ion beam.

Statistically relevant subsurface and 3D data analysis

Data acquisition for much larger volumes within a shorter amount of time.

Accurate and repeatable cut placement

Same coincident point for all tree beams (SEM / (P)FIB / laser) enables accurate and repeatable cut placement and 3D characterization.

Fast characterization of deep subsurface features

Extraction of subsurface TEM lamella or chunks for 3D analysis.

High throughput processing of challenging materials

Includes non-conductive or ion-beam-sensitive samples.

Fast and easy characterization of air-sensitive samples

No need to transfer samples between different instruments for cross-sectioning and imaging.

Shares all capabilities of the Helios 5 platform

High-quality TEM and APT sample preparation and high-resolution imaging capabilities.

| Laser specifications | ||

|---|---|---|

| Laser integration |

| |

| First Harmonic |

| 1030 nm (IR) <280 fs |

| Second Harmonic |

| 515 nm (green) |

| Optics |

|

|

| Repetition rate | • 1 kHz – 1 MHz | |

| Beam position accuracy | • <250 nm | |

| Protective shutter | • Automated SEM/PFIB protective shutter | |

| Software | • Laser control software | |

| Safety | • Interlocked laser enclosure (Class 1 laser safety) | |

On demand webinar: Discover the all new Helios 5 Laser PFIB

Register for our recorded webinar and learn how the combination of fs-Laser and PFIB provides mm-scale subsurface and 3D analysis at nm resolution and enables new workflows such as fast characterization of air sensitive samples and multi-scale correlative microscopy with deep subsurface sample extraction.

Latest application developments of multiple ion species plasma FIB technology

Register for our live webinar and learn how leading research labs are using our new Thermo Scientific Helios 5 Laser PFIB and Thermo Scientific Helios 5 Hydra DualBeam to advance their materials characterization.

On demand webinar: Discover the all new Helios 5 Laser PFIB

Register for our recorded webinar and learn how the combination of fs-Laser and PFIB provides mm-scale subsurface and 3D analysis at nm resolution and enables new workflows such as fast characterization of air sensitive samples and multi-scale correlative microscopy with deep subsurface sample extraction.

Latest application developments of multiple ion species plasma FIB technology

Register for our live webinar and learn how leading research labs are using our new Thermo Scientific Helios 5 Laser PFIB and Thermo Scientific Helios 5 Hydra DualBeam to advance their materials characterization.

Quality control and failure analysis

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

(S)TEM Sample Preparation

DualBeam microscopes enable the preparation of high-quality, ultra-thin samples for (S)TEM analysis. Thanks to advanced automation, users with any experience level can obtain expert-level results for a wide range of materials.

APT Sample Preparation

Atom probe tomography (APT) provides atomic-resolution 3D compositional analysis of materials. Focused ion beam (FIB) microscopy is an essential technique for high-quality, orientation, and site-specific sample preparation for APT characterization.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Multi-scale analysis

Novel materials must be analyzed at ever higher resolution while retaining the larger context of the sample. Multi-scale analysis allows for the correlation of various imaging tools and modalities such as X-ray microCT, DualBeam, Laser PFIB, SEM and TEM.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

(S)TEM Sample Preparation

DualBeam microscopes enable the preparation of high-quality, ultra-thin samples for (S)TEM analysis. Thanks to advanced automation, users with any experience level can obtain expert-level results for a wide range of materials.

APT Sample Preparation

Atom probe tomography (APT) provides atomic-resolution 3D compositional analysis of materials. Focused ion beam (FIB) microscopy is an essential technique for high-quality, orientation, and site-specific sample preparation for APT characterization.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Multi-scale analysis

Novel materials must be analyzed at ever higher resolution while retaining the larger context of the sample. Multi-scale analysis allows for the correlation of various imaging tools and modalities such as X-ray microCT, DualBeam, Laser PFIB, SEM and TEM.