Search Thermo Fisher Scientific

- Contact Us

- Quick Order

-

Don't have an account ? Create Account

Search Thermo Fisher Scientific

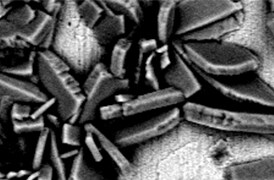

Sample preparation for scanning/transmission electron microscopy (S/TEM) analysis is considered to be one of the most critical but challenging and time-consuming tasks in materials characterization labs. Conventional methods used to prepare ultra-thin samples required for S/TEM are slow, typically requiring many hours or even days of effort by highly trained personnel. This is further complicated by the variety of different materials and the need for site-specific information. For more than 30 years, Thermo Fisher Scientific has been continuously developing and optimizing sample preparation instruments and introducing software that enable in situ TEM sample preparation that allows researchers to accelerate their research and fast-track innovation.

Thermo Fisher Scientific has 30+ years of TEM sample preparation expertise. In 1993, we introduced DualBeam (FIB-SEM, focused ion beam – scanning electron microscopy) technology to give you cutting-edge sample preparation tools that are accessible, robust, and reliable. This begins with a highly stable column and high-quality source, which allows for excellent performance even at low voltages. Final polishing of the lamella using energies as low as 500 V greatly reduces damage, even to beam sensitive materials, and delivers unrivaled sample quality. For gallium-free sample preparation, Thermo Fisher Scientific has a broad portfolio of plasma FIB products, including the Thermo Scientific Helios Hydra DualBeam, which offers fast switching between four ion beam species; xenon, argon, oxygen, and nitrogen.

Additionally, Thermo Scientific SmartAlign Technology eliminates the need for any user alignments of the electron column, which not only minimizes maintenance, but also increases your productivity. Auto-tuning tools, embedded into the user interface, further increasing your ability to get high-quality images, tuning the image up to 10-times faster than standard manual alignment.

Quality hardware is supported by a suite of software solutions that enhance and simplify sample preparation. Thermo Scientific AutoTEM 5 Software enables fully automated in situ lamella preparation and lift-out, allowing even novice users to produce quality samples. This greatly expands the accessibility of the instrument, thereby increasing throughput as sample preparation is no longer reliant on expert operation. Moreover, full automation allows maximum utilization of system time with unattended overnight operation, resulting in greatly enhanced productivity.

TEM sample preparation is part of a multi-scale, multi-modal workflow that includes microCT, (P)FIB-SEM, and (S)TEM. First, data is acquired using the microCT, followed by data reconstruction and analysis using Thermo Scientific Avizo Software. Avizo Software visualizes the data and enables you to precisely locate the suitable regions of interest (ROI) for further exploration of the sample. When the ROI is identified, the workflow progresses through higher-resolution imaging and sample preparation with a plasma-focused ion beam (PFIB) DualBeam to atomic-scale analysis in a transmission electron microscope (TEM). When combined, these technologies provide a complete understanding of sample structure and composition, accelerating development of novel materials.

Joseph Richard Michael, who worked many years at Sandia National Laboratories in Materials, Physical and Chemical Sciences, tells his story of how TEM sample preparation changed the way he and his fellow materials scientists were able to do their research.

In this podcast we hear David Foord, product director and materials scientist, in talks with some of his colleagues at Thermo Fisher Scientific. What started as a casual internal conversation around the driving force behind 30+ years of ion beam technology was so interesting that we wanted to share David’s story with you. This podcast proves that people at Thermo Fisher Scientific drive the field of materials science forward with solution-focused innovation that always circles around one question: What problem is this technology going to solve?

Learn how advanced automation capabilities, increased robustness and stability enhancements in the Helios 5 and AutoTEM 5 software can significantly increase sample preparation throughout by allowing unattended and even overnight operation.

Diminish the challenges associated with focused ion beam (FIB) sample preparation for high resolution transmission electron microscopy (HR-TEM). Dr. Chengge Jiao, Staff Scientist of Applications Development at Thermo Fisher Scientific, explains how to tailor processing conditions and select the right FIB ion species for certain groups of materials to achieve optimized results.

Listen to Dr. Joakim Reuteler, a FIB expert from ETH Zurich, discuss how gallium focused ion beam, multi-ion species plasma FIB, and ultra-short-pulse laser milling can help you prepare samples for a wide range of applications.

Learn how advanced automation capabilities, increased robustness and stability enhancements in the Helios 5 and AutoTEM 5 software can significantly increase sample preparation throughout by allowing unattended and even overnight operation.

Diminish the challenges associated with focused ion beam (FIB) sample preparation for high resolution transmission electron microscopy (HR-TEM). Dr. Chengge Jiao, Staff Scientist of Applications Development at Thermo Fisher Scientific, explains how to tailor processing conditions and select the right FIB ion species for certain groups of materials to achieve optimized results.

Listen to Dr. Joakim Reuteler, a FIB expert from ETH Zurich, discuss how gallium focused ion beam, multi-ion species plasma FIB, and ultra-short-pulse laser milling can help you prepare samples for a wide range of applications.

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

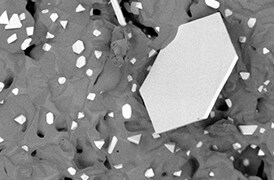

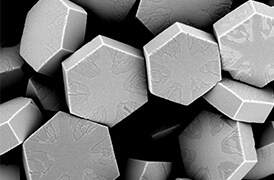

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Battery development is enabled by multi-scale analysis with microCT, SEM and TEM, Raman spectroscopy, XPS, and digital 3D visualization and analysis. Learn how this approach provides the structural and chemical information needed to build better batteries.

Polymer microstructure dictates the material’s bulk characteristics and performance. Electron microscopy enables comprehensive microscale analysis of polymer morphology and composition for R&D and quality control applications.

Effective production of metals requires precise control of inclusions and precipitates. Our automated tools can perform a variety of tasks critical for metal analysis including; nanoparticle counting, EDS chemical analysis and TEM sample preparation.

Catalysts are critical for a majority of modern industrial processes. Their efficiency depends on the microscopic composition and morphology of the catalytic particles; EM with EDS is ideally suited for studying these properties.

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.