Search Thermo Fisher Scientific

- Contact Us

- Quick Order

-

Don't have an account ? Create Account

Search Thermo Fisher Scientific

Modern cutting-edge metals are increasingly engineered at the nanoscale to enhance their durability, reliability, and cost. Even traditional processes are now augmented with microscopic inspection to determine the resulting material’s elemental and structural composition.

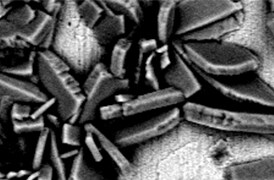

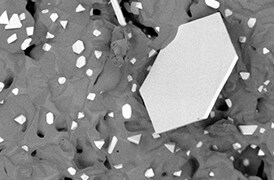

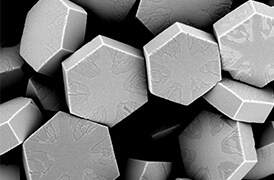

In particular, the effective production of metals requires precise control of inclusions and precipitates. Depending on their consistency and distribution, these can either strengthen the material or act as contaminants, greatly impacting quality and lifetime. These microscopic properties can include;

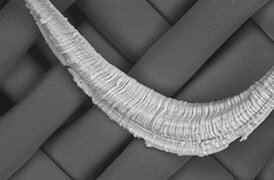

Historically, researchers have used optical microscopy to rate the size and number of inclusions, but this method does not provide any elemental information. Even optical emission spectroscopy, which can determine the elemental ratios of inclusions, does not accurately characterize the shape and composition of individual inclusions. Electron microscopy techniques have also been used for metal analysis, with scanning electron microscopy (SEM) capable of visualizing larger oxide inclusions, whereas transmission electron microscopy (TEM) is generally required to study features smaller than 100 nm. TEM analysis, however, has previously required manual particle counting and analysis, limiting the amount of data that could be collected to several dozen particles per day.

Thermo Fisher Scientific provides a range of electron microscopy solutions that make metal analysis not only more informative but also far more rapid. Thanks to our unique automation capabilities, a thorough overview of the elemental and structural composition of hundreds, if not thousands, of precipitates is possible in a manner of hours, as compared to the few dozen that would be found in a day of manual analysis. Not only is statistical information on the bulk available, but individual precipitates can also be seen with high detail, providing a multi-scale overview of the metal.

Our robust, automated instruments can perform a variety of critical tasks including:

Phenom ParticleX Steel Desktop SEM inclusion analysis short demonstration.

ParticleX Steel Desktop SEM - Workflow introduction.

Axia ChemiSEM provides high-quality imaging of steel samples to aid in the production of high-value steels.

Axia ChemiSEM identifies composition on-the-fly

HSLA steel lamella characterization of Nb precipitates by Automated Particle Workflow (APW).

3D EDS TEM tomography of precipitates in an AlMgSi alloy.

High resolution APW showing complex features in additively manufactured stainless steel.

Maps and Avizo2D recordings (left and right) running side by side during an acquisition.

Webinar: Nanoparticle Characterization by Automated TEM.

Webinar: Correlative Microscopy for Aerospace and Defense Industries

Documents

Hao Wu, Guohua Fan, Lin Geng, Xiping Cui, Meng Huang

Yu Sun, Rainer J. Hebert, Mark Aindow

Behnam Amin-Ahmadi,⁎, Joseph G. Pauza, Ali Shamimi, Tom W. Duerig, Ronald D. Noebe, Aaron P. Stebner

Yu Sun, Rainer J. Hebert, Mark Aindow

Yu Sun, Rainer J. Hebert, Mark Aindow

“Formation of White Etching Areas in SAE 52100 Bearing Steel under Rolling Contact Fatigue − Influence of Diffusible Hydrogen”

M. Oezel, A. Schwedt, T. Janitzky, R. Kelley, C.Bouchet-Marquis, L. Pullan, C. Broeckmann, J. Mayer

Wear, Volumes 414-415, November 2018, Pages 352-365.

“Industrial Gear Oils: Tribological Performance and Subsurface Changes”

Aduragbemi Adebogun, Robert Hudson, Angela Breakspear, Chris Warrens, Ali Gholinia, Allan Matthews, Philip Withers Tribology Letters (2018) 66:65.

“Insight into atmospheric pitting corrosion of carbon steel via a dual-beam FIB/SEM system associated with high-resolution TEM”

Corrosion Science 152 (2019) 226–233.

“Micro-tensile strength of a welded turbine disc superalloy”

K.M. Oluwasegun, C.Cooper, Y.L.Chiu, I.P.Jones, H.Y.Li, G.Baxter

Materials Science & Engineering A 596 (2014) 229–235.

“Application of Plasma FIB to Analyze a Single Oxide Inclusion in Steel”

D. Kumar, N.T. Nuhfer, M.E. Ferreira and P.C. Pistorius

Metallurgical and Materials Transactions B, Volume 50B, June 2019, Pages 1124-1127.

Phenom ParticleX Steel Desktop SEM inclusion analysis short demonstration.

ParticleX Steel Desktop SEM - Workflow introduction.

Axia ChemiSEM provides high-quality imaging of steel samples to aid in the production of high-value steels.

Axia ChemiSEM identifies composition on-the-fly

HSLA steel lamella characterization of Nb precipitates by Automated Particle Workflow (APW).

3D EDS TEM tomography of precipitates in an AlMgSi alloy.

High resolution APW showing complex features in additively manufactured stainless steel.

Maps and Avizo2D recordings (left and right) running side by side during an acquisition.

Webinar: Nanoparticle Characterization by Automated TEM.

Webinar: Correlative Microscopy for Aerospace and Defense Industries

Documents

Hao Wu, Guohua Fan, Lin Geng, Xiping Cui, Meng Huang

Yu Sun, Rainer J. Hebert, Mark Aindow

Behnam Amin-Ahmadi,⁎, Joseph G. Pauza, Ali Shamimi, Tom W. Duerig, Ronald D. Noebe, Aaron P. Stebner

Yu Sun, Rainer J. Hebert, Mark Aindow

Yu Sun, Rainer J. Hebert, Mark Aindow

“Formation of White Etching Areas in SAE 52100 Bearing Steel under Rolling Contact Fatigue − Influence of Diffusible Hydrogen”

M. Oezel, A. Schwedt, T. Janitzky, R. Kelley, C.Bouchet-Marquis, L. Pullan, C. Broeckmann, J. Mayer

Wear, Volumes 414-415, November 2018, Pages 352-365.

“Industrial Gear Oils: Tribological Performance and Subsurface Changes”

Aduragbemi Adebogun, Robert Hudson, Angela Breakspear, Chris Warrens, Ali Gholinia, Allan Matthews, Philip Withers Tribology Letters (2018) 66:65.

“Insight into atmospheric pitting corrosion of carbon steel via a dual-beam FIB/SEM system associated with high-resolution TEM”

Corrosion Science 152 (2019) 226–233.

“Micro-tensile strength of a welded turbine disc superalloy”

K.M. Oluwasegun, C.Cooper, Y.L.Chiu, I.P.Jones, H.Y.Li, G.Baxter

Materials Science & Engineering A 596 (2014) 229–235.

“Application of Plasma FIB to Analyze a Single Oxide Inclusion in Steel”

D. Kumar, N.T. Nuhfer, M.E. Ferreira and P.C. Pistorius

Metallurgical and Materials Transactions B, Volume 50B, June 2019, Pages 1124-1127.

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

More than ever, modern manufacturing necessitates reliable, quality components. With scanning electron microscopy, parts cleanliness analysis can be brought inhouse, providing you with a broad range of analytical data and shortening your production cycle.

(S)TEM Sample Preparation

DualBeam microscopes enable the preparation of high-quality, ultra-thin samples for (S)TEM analysis. Thanks to advanced automation, users with any experience level can obtain expert-level results for a wide range of materials.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

Energy Dispersive Spectroscopy

Energy dispersive spectroscopy (EDS) collects detailed elemental information along with electron microscopy images, providing critical compositional context for EM observations. With EDS, chemical composition can be determined from quick, holistic surface scans down to individual atoms.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

_Technique_800x375_144DPI.jpg)

3D EDS Tomography

Modern materials research is increasingly reliant on nanoscale analysis in three dimensions. 3D characterization, including compositional data for full chemical and structural context, is possible with 3D EM and energy dispersive X-ray spectroscopy.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

X-Ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy (XPS) enables surface analysis, providing elemental composition as well as the chemical and electronic state of the top 10 nm of a material. With depth profiling, XPS analysis extends to compositional insight of layers.

The Automated NanoParticle Workflow (APW) is a transmission electron microscope workflow for nanoparticle analysis, offering large area, high resolution imaging and data acquisition at the nanoscale, with on-the-fly processing.

(S)TEM Sample Preparation

DualBeam microscopes enable the preparation of high-quality, ultra-thin samples for (S)TEM analysis. Thanks to advanced automation, users with any experience level can obtain expert-level results for a wide range of materials.

3D Materials Characterization

Development of materials often requires multi-scale 3D characterization. DualBeam instruments enable serial sectioning of large volumes and subsequent SEM imaging at nanometer scale, which can be processed into high-quality 3D reconstructions of the sample.

Energy Dispersive Spectroscopy

Energy dispersive spectroscopy (EDS) collects detailed elemental information along with electron microscopy images, providing critical compositional context for EM observations. With EDS, chemical composition can be determined from quick, holistic surface scans down to individual atoms.

_Technique_800x375_144DPI.jpg)

EDS Elemental Analysis

Thermo Scientific Phenom Elemental Mapping Software provides fast and reliable information on the distribution of chemical elements within a sample.

_Technique_800x375_144DPI.jpg)

3D EDS Tomography

Modern materials research is increasingly reliant on nanoscale analysis in three dimensions. 3D characterization, including compositional data for full chemical and structural context, is possible with 3D EM and energy dispersive X-ray spectroscopy.

EDS Analysis with ChemiSEM Technology

Energy dispersive X-ray spectroscopy for materials characterization.

Cross-sectioning

Cross sectioning provides extra insight by revealing sub-surface information. DualBeam instruments feature superior focused ion beam columns for high-quality cross sectioning. With automation, unattended high-throughput processing of samples is possible.

In Situ experimentation

Direct, real-time observation of microstructural changes with electron microscopy is necessary to understand the underlying principles of dynamic processes such as recrystallization, grain growth, and phase transformation during heating, cooling, and wetting.

Particle analysis

Particle analysis plays a vital role in nanomaterials research and quality control. The nanometer-scale resolution and superior imaging of electron microscopy can be combined with specialized software for rapid characterization of powders and particles.

X-Ray Photoelectron Spectroscopy

X-ray photoelectron spectroscopy (XPS) enables surface analysis, providing elemental composition as well as the chemical and electronic state of the top 10 nm of a material. With depth profiling, XPS analysis extends to compositional insight of layers.

The Automated NanoParticle Workflow (APW) is a transmission electron microscope workflow for nanoparticle analysis, offering large area, high resolution imaging and data acquisition at the nanoscale, with on-the-fly processing.

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.