Search Thermo Fisher Scientific

- Contact Us

- Quick Order

-

Don't have an account ? Create Account

Search Thermo Fisher Scientific

Thermo Scientific Phenom ParticleX and Perception Desktop SEMs deliver a comprehensive plug-and-play SEM-EDS software solution for particle analysis workflows. Featuring automated characterization, verification, and classification of materials, the instruments support your production with fast, accurate, and reliable data that adheres to industry regulations and standards.

Features include:

Perform technical cleanliness at the microscale with the multi-purpose Phenom ParticleX TC Desktop SEM.

Automate steel inclusion analysis and quickly respond to faults and failures with the Phenom ParticleX Steel Desktop SEM.

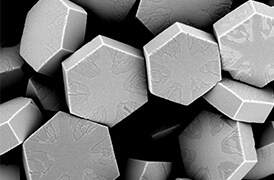

Analyze samples up to 100 mm x 100 mm and ensure purity at the microscale with the Phenom ParticleX AM Desktop SEM.

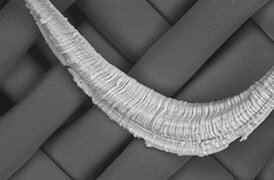

Speed up gunshot residue analysis with the automated, long-lasting Phenom Perception GSR Desktop SEM.

Effectively trace contaminants in battery materials with the Phenom ParticleX Battery Desktop SEM.

In each on-demand webinar, our expert will focus on one particular analysis application and how the Phenom ParticleX Desktop SEM overcomes some of the most common challenges. See the abstracts for individual sessions below.

In each on-demand webinar, our expert will focus on one particular analysis application and how the Phenom ParticleX Desktop SEM overcomes some of the most common challenges. See the abstracts for individual sessions below.

Modern industry demands high throughput with superior quality, a balance that is maintained through robust process control. SEM and TEM tools with dedicated automation software provide rapid, multi-scale information for process monitoring and improvement.

Quality control and assurance are essential in modern industry. We offer a range of EM and spectroscopy tools for multi-scale and multi-modal analysis of defects, allowing you to make reliable and informed decisions for process control and improvement.

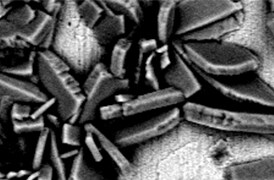

More than ever, modern manufacturing necessitates reliable, quality components. With scanning electron microscopy, parts cleanliness analysis can be brought inhouse, providing you with a broad range of analytical data and shortening your production cycle.

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Battery development is enabled by multi-scale analysis with microCT, SEM and TEM, Raman spectroscopy, XPS, and digital 3D visualization and analysis. Learn how this approach provides the structural and chemical information needed to build better batteries.

Every component in a modern vehicle is designed for safety, efficiency, and performance. Detailed characterization of automotive materials with electron microscopy and spectroscopy informs critical process decisions, product improvements, and new materials.

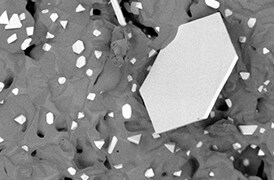

Effective production of metals requires precise control of inclusions and precipitates. Our automated tools can perform a variety of tasks critical for metal analysis including; nanoparticle counting, EDS chemical analysis and TEM sample preparation.

Novel materials research is increasingly interested in the structure of low-dimensional materials. Scanning transmission electron microscopy with probe correction and monochromation allows for high-resolution two-dimensional materials imaging.

Polymer microstructure dictates the material’s bulk characteristics and performance. Electron microscopy enables comprehensive microscale analysis of polymer morphology and composition for R&D and quality control applications.

Materials have fundamentally different properties at the nanoscale than at the macroscale. To study them, S/TEM instrumentation can be combined with energy dispersive X-ray spectroscopy to obtain nanometer, or even sub-nanometer, resolution data.

Catalysts are critical for a majority of modern industrial processes. Their efficiency depends on the microscopic composition and morphology of the catalytic particles; EM with EDS is ideally suited for studying these properties.

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.