Search Thermo Fisher Scientific

Ambient Storage

Designed for easy integration into automated systems

Thermo Scientific Cytomat random access storage hotels are designed to integrate into any automated system. From benchtop to floor standing models, Cytomat Hotels can accommodate from 42 to 1008 shallow well plates, while the integrated plate shuttle system (PSS) can handle all SBS standard microplate formats, including deep-well plates and tip boxes. The system can also be optimized for petri dish or protein crystallography applications. In addition, a high capacity sequential plate storage device is available.

Most compact ambient, random access storage hotel with a capacity of up to 42 standard microplates.

Fastest, high-capacity ambient, random access storage hotel for up to 210 standard microplates with standard or perspex housing.

Ideal for highest capacity ambient, random access storage hotel for up to 504 standard microplates.

The Cytomat system delivers the microplate to a single point, offering “easy-teach” integration for any automated system. A single loading and unloading point – the transfer station – makes teaching simple and cuts down the programming time, making for an extremely robot-friendly design.

These transfer stations offer a versatile placement of the Cytomat in the lab.

Standard transfer station

This standard transfer station supplies the microplate in portrait format. A 90° turnable version is available for landscape presentation.

Linear transfer station

This linear transfer station is available in different lengths (300mm, 400mm, 500mm, and customized lengths) for extended reach and delivers the microplate in portrait format. Additional options are available for landscape presentation and lateral movement.

Swap station (180°)

This swap station accelerates your lab automation handling system by providing two plate positions.

Plate lift

This plate lift is stepper motor driven (SMD) and offers microplate movement to a predefined height within a 500 mm stroke.

The right options to match your application and automation needs with internal barcode readers, stackers, copper chambers and more.

Internal barcode reader

The barcode reader is located on the plate handler, allowing retrieval of information on every position, even when manually loaded.

Stacker

The stainless steel, autoclavable Cytomat Stacker accommodates all standard microplates. Dedicated pitch sizes are available to optimize capacity for different types of microplates.

Copper chamber

Solid pure antimicrobial copper chambers are proven to be effective against contamination.

- O2-control

- hH – High humidity up to 98% at 37°C

- Door left hinges (DL)

- H2O2 generator ports

- SiLA interface option

Many more options available

The Cytomat system delivers the microplate to a single point, offering “easy-teach” integration for any automated system. A single loading and unloading point – the transfer station – makes teaching simple and cuts down the programming time, making for an extremely robot-friendly design.

These transfer stations offer a versatile placement of the Cytomat in the lab.

Standard transfer station

This standard transfer station supplies the microplate in portrait format. A 90° turnable version is available for landscape presentation.

Linear transfer station

This linear transfer station is available in different lengths (300mm, 400mm, 500mm, and customized lengths) for extended reach and delivers the microplate in portrait format. Additional options are available for landscape presentation and lateral movement.

Swap station (180°)

This swap station accelerates your lab automation handling system by providing two plate positions.

Plate lift

This plate lift is stepper motor driven (SMD) and offers microplate movement to a predefined height within a 500 mm stroke.

The right options to match your application and automation needs with internal barcode readers, stackers, copper chambers and more.

Internal barcode reader

The barcode reader is located on the plate handler, allowing retrieval of information on every position, even when manually loaded.

Stacker

The stainless steel, autoclavable Cytomat Stacker accommodates all standard microplates. Dedicated pitch sizes are available to optimize capacity for different types of microplates.

Copper chamber

Solid pure antimicrobial copper chambers are proven to be effective against contamination.

- O2-control

- hH – High humidity up to 98% at 37°C

- Door left hinges (DL)

- H2O2 generator ports

- SiLA interface option

Many more options available

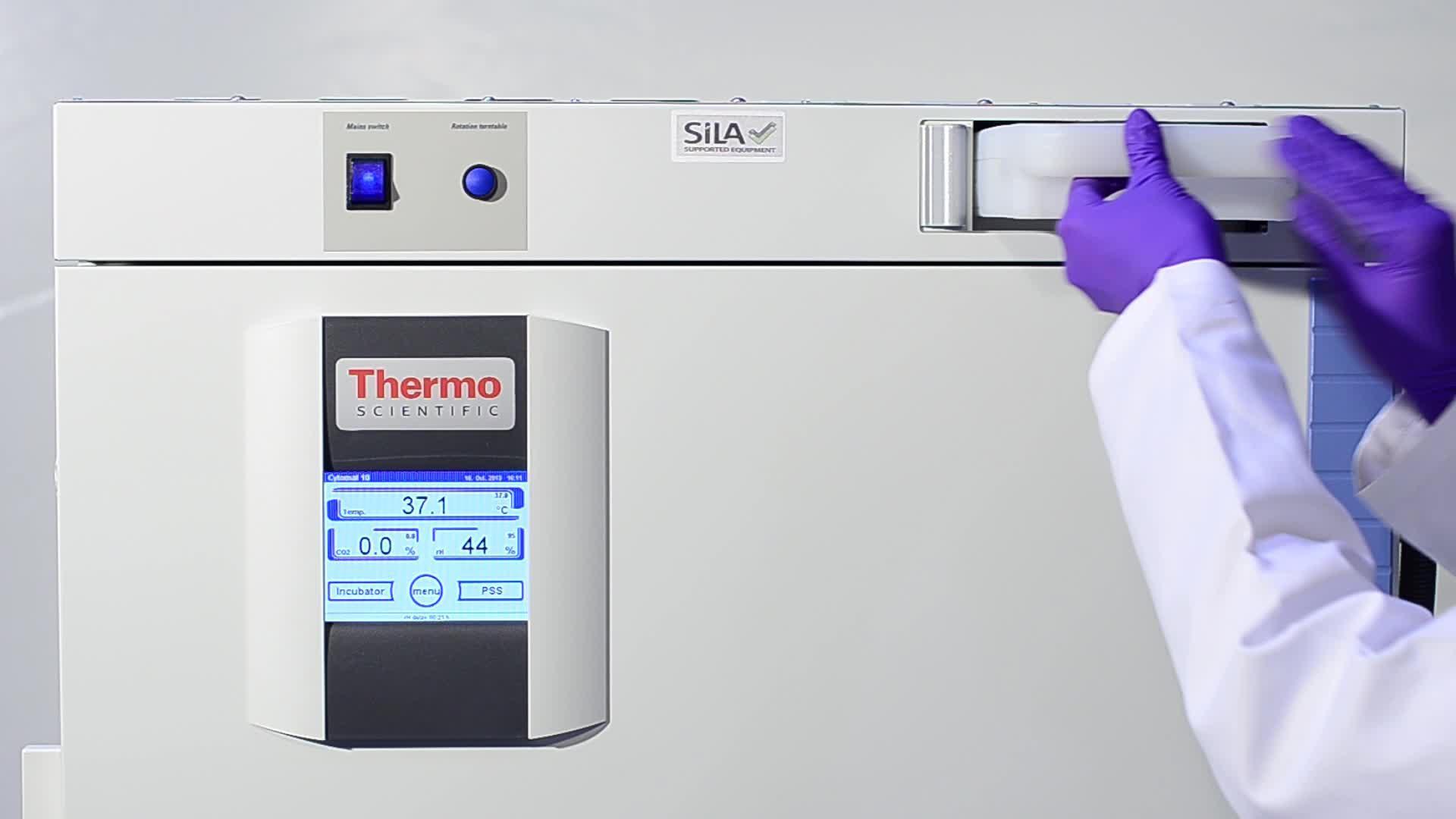

The Cytomat 10 automated incubator series combines superior environmental control, fast access times and versatility, making it the ideal choice for cell-based workflows requiring larger capacity incubation.