Search Thermo Fisher Scientific

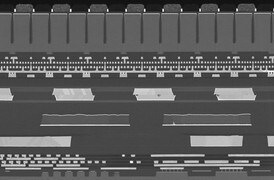

The Thermo Scientific ExSolve wafer TEM prep (WTP) DualBeam (FIB-SEM) dramatically reduces the cost and increases the speed of sample preparation, providing semiconductor and data storage manufacturers with quick and easy access to the data they need to verify and monitor process performance. The ExSolve DualBeam can prepare site-specific TEM lamella, sampling many sites per wafer in a fully-automated process inside the fab, giving semiconductor manufacturers much more information than conventional approaches, while at the same time reducing the capital cost of sample preparation by up to 70 percent.

The ExSolve WTP DualBeam system is an automated, high-throughput sample preparation system that can prepare site-specific, 20 nm thick lamellae on whole wafers up to 300 mm in diameter. It is part of a fast, complete workflow that includes Thermo Scientific TEMLink, and the Thermo Scientific Metrios TEM. The ExSolve DualBeam includes FOUP handling and is designed to be located in the fab near the manufacturing line.

The ExSolve WTP DualBeam workflow addresses the needs of customers that require automated, high-throughput sampling at advanced technology nodes. It complements the capabilities of the Thermo Scientific Helios NanoLab DualBeam 1200AT, which provides more flexible, operator-directed, sample preparation methods, along with additional capabilities such as high-resolution scanning electron microscopy (SEM) imaging and analysis.

Semiconductor Pathfinding and Research

Advanced electron microscopy, focused ion beam, and associated analytical techniques for identifying viable solutions and design methods for the fabrication of high-performance semiconductor devices.

Yield Ramp and Metrology

We offer advanced analytical capabilities for defect analysis, metrology, and process control, designed to help increase productivity and improve yield across a range of semiconductor applications and devices.

Semiconductor Failure Analysis

Increasingly complex semiconductor device structures result in more places for failure-inducing defects to hide. Our next-generation workflows help you localize and characterize subtle electrical issues that affect yield, performance, and reliability.

Physical and Chemical Characterization

Ongoing consumer demand drives the creation of smaller, faster, and cheaper electronic devices. Their production relies on high-productivity instruments and workflows that image, analyze, and characterize a broad range of semiconductor and display devices.

Sample Preparation of Semiconductor Devices

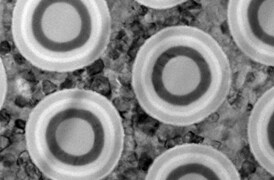

Thermo Scientific DualBeam systems provide accurate TEM sample preparation for atomic-scale analysis of semiconductor devices. Automation and advanced machine learning technologies produce high-quality samples, at the correct location, and a low cost per sample.

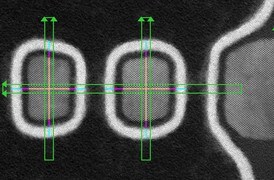

TEM Metrology

Advanced and automated TEM metrology routines deliver significantly greater precision than manual methods. This allows users to generate large amounts of statistically relevant data, with sub-angstrom-level specificity, that is free of operator bias.

Sample Preparation of Semiconductor Devices

Thermo Scientific DualBeam systems provide accurate TEM sample preparation for atomic-scale analysis of semiconductor devices. Automation and advanced machine learning technologies produce high-quality samples, at the correct location, and a low cost per sample.

TEM Metrology

Advanced and automated TEM metrology routines deliver significantly greater precision than manual methods. This allows users to generate large amounts of statistically relevant data, with sub-angstrom-level specificity, that is free of operator bias.

Electron microscopy services for

semiconductors

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.