Search Thermo Fisher Scientific

Electrostatic discharge (ESD) causes localized increases in temperature that can damage small features and structures that make up today’s semiconductor devices and integrated circuits. As these structures and devices become smaller and more complex in design, isolating such electrical faults becomes more challenging. This means advanced and highly sensitive testing equipment is needed to ensure that these devices can survive electrostatic discharge. This equipment can also help to prove that devices are in compliance with national, international, and industry ESD test standards.

For example, the most common ESD compliance test, called human body model (HBM) testing, simulates the effect of a human discharging electrical energy into an electronic component. Another example is charged device model (CDM) testing, where a discharge is simulated coming from the device to an external point.

Thermo Fisher Scientific offers a range of equipment that suits all your ESD testing needs, including instruments for transmission-line pulse (TLP), HBM, and CDM testing. The exact tool required will depend on the size and complexity of the device, so be sure to visit our product pages on this website for more information.

ESD Semiconductor Qualification

Every electrostatic discharge (ESD) control plan is required to identify devices that are sensitive to ESD. We offer a complete suite of test systems to help with your device qualification requirements.

Power Semiconductor Device Analysis

Power devices pose unique challenges for localizing faults, primarily as a result of power device architecture and layout. Our power device analysis tools and workflows quickly pinpoint fault locations at operating conditions and provide precise, high-throughput analysis for characterization of materials, interfaces and device structures.

Display Module Failure Analysis

Evolving display technologies aim to improve display quality and light conversion efficiency to support applications in different industry sectors, while continuing to reduce production costs. Our process metrology, failure analysis and research and development solutions help display companies solve these challenges.

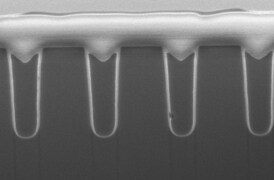

Semiconductor Materials and Device Characterization

As semiconductor devices shrink and become more complex, new designs and structures are needed. High-productivity 3D analysis workflows can shorten device development time, maximize yield, and ensure that devices meet the future needs of the industry.

Electron microscopy services for

semiconductors

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.