Search Thermo Fisher Scientific

Materials Science

Hot Stage Microscopy

An SEM heating stage offers high quality in situ imaging and analysis at high temperatures.

Join the conversation

Hot stage microscopy

Real-world materials applications often take place under variable environmental conditions, including high temperatures. The behavior of your heated material as it recrystallizes, melts, and deforms can inform critical macro- and microscopic observations, such as how a manufactured part might respond to stress or how feed materials behave during production. As a sample’s response to heat is a dynamic process, it must be paired with dynamic observation for accurate insight. Modern heating stages in electron microscopes allow for in situ experiments for high-resolution observation of heated materials. These demanding experiments are capable of linking sample morphology, environment, and thermodynamics, and can help you control the corresponding behavior of the bulk material.

SEM heating stages

There are many considerations when operating electron microscopes at elevated temperatures, such as the desired temperature range, sample size, and chemical environment. The following table shows what is possible with Thermo Scientific temperature stages.

Name | Application | Temperature | Max. Sample Size | Environment |

High vacuum heating stage | General-purpose heating, high resolution imaging, in-column detection, fast processes, electron-backscatter diffraction (EBSD) | Up to 1100°C (EBSD up to 900°C) | 10 mm | High vacuum |

Environmental SEM (ESEM) stage | Heating in gaseous environment: oxidation or other chemical reactions | Up to 1000°C or 1400°C, depending on the model | 5 mm | ESEM |

µHeater | Powder heating, chunk lift-out studies (DualBeam), STEM imaging, high-temperature EBSD and EDS, ramp rate of 10,000°C/s | Up to 1200°C | 50 µm | Any |

Cooling stage, WetSTEM | Precise control over humidity, wetting studies, modest heating | -20°C to +60°C | 3 mm | ESEM |

Mixture of magnetite and hematite nanoparticles heated at 1030 °C.

Backscattered electron image (left) and EDS maps of iron and oxygen (right) acquired simultaneously.

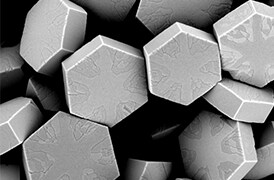

Texture development on implant material. As the temperature increases from 700 °C to 1300 °C

we can observe a completely different surface structure. Pressure: 120 Pa.

Two-phase Co-Sb alloy during heating to 700°C on the High Vacuum Heating Stage. The antimony-rich

phase sublimated during heating, causing exposure of the second phase.

Documents

Mixture of magnetite and hematite nanoparticles heated at 1030 °C.

Backscattered electron image (left) and EDS maps of iron and oxygen (right) acquired simultaneously.

Texture development on implant material. As the temperature increases from 700 °C to 1300 °C

we can observe a completely different surface structure. Pressure: 120 Pa.

Two-phase Co-Sb alloy during heating to 700°C on the High Vacuum Heating Stage. The antimony-rich

phase sublimated during heating, causing exposure of the second phase.

Documents

Fundamental Materials Research

Novel materials are investigated at increasingly smaller scales for maximum control of their physical and chemical properties. Electron microscopy provides researchers with key insight into a wide variety of material characteristics at the micro- to nano-scale.

Battery Research

Battery development is enabled by multi-scale analysis with microCT, SEM and TEM, Raman spectroscopy, XPS, and digital 3D visualization and analysis. Learn how this approach provides the structural and chemical information needed to build better batteries.

Metals Research

Effective production of metals requires precise control of inclusions and precipitates. Our automated tools can perform a variety of tasks critical for metal analysis including; nanoparticle counting, EDS chemical analysis and TEM sample preparation.

Polymers Research

Polymer microstructure dictates the material’s bulk characteristics and performance. Electron microscopy enables comprehensive microscale analysis of polymer morphology and composition for R&D and quality control applications.

Nanoparticles

Materials have fundamentally different properties at the nanoscale than at the macroscale. To study them, S/TEM instrumentation can be combined with energy dispersive X-ray spectroscopy to obtain nanometer, or even sub-nanometer, resolution data.

Forensics

Micro-traces of crime scene evidence can be analyzed and compared using electron microscopy as part of a forensic investigation. Compatible samples include glass and paint fragments, tool marks, drugs, explosives, and GSR (gunshot residue).

Catalysis Research

Catalysts are critical for a majority of modern industrial processes. Their efficiency depends on the microscopic composition and morphology of the catalytic particles; EM with EDS is ideally suited for studying these properties.

Automotive Materials Testing

Every component in a modern vehicle is designed for safety, efficiency, and performance. Detailed characterization of automotive materials with electron microscopy and spectroscopy informs critical process decisions, product improvements, and new materials.

Fibers and Filters

The diameter, morphology and density of synthetic fibers are key parameters that determine the lifetime and functionality of a filter. Scanning electron microscopy (SEM) is the ideal technique for quickly and easily investigating these features.

Electron microscopy services for

the materials science

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.