Search Thermo Fisher Scientific

ICP-OES Data Analysis

Inductively coupled plasma optical emission spectroscopy (ICP-OES) data analysis is a multi-step process. First, one must select the correct sample introduction method, as well as which plasma view and configuration to use. Then, method development must be carried out, taking into account possible interferences that need to be corrected for. Finally, evaluation of the method and its analytical results is conducted.

ICP-OES considerations

- Sample introduction—Specific sample introduction processes and settings allow either more or less of the sample to reach the plasma. This can increase sensitivity, but it can also have a negative impact on plasma stability, especially if complex matrices are introduced.

- Wavelength selection—Spectral interferences should be avoided whenever possible. To expand the linear range, multiple wavelengths with varying sensitivity can be chosen for each element..

- Plasma view—There are two views available for the collection of light: axial view and radial view. With the axial view, the light from the plasma channel is detected; high sensitivity and good detection limits can be achieved but this view is also more affected by interferences. The radial view allows for a high linear dynamic range and better stability of the instrument (with high matrix samples), but is also less sensitive.

- Acquisition parameters—The integration or exposure time is the time the chip detects signals. When measuring lower concentrations, integration time can be extended to achieve better detection limits.

Interferences

Ideally, physical and chemical effects should be experimentally eliminated and the use of a solid state detector should allow the analyst to select an interference-free wavelength for analysis. However, if this is not possible, then alternative techniques must be used. There are three main types of interferences that are encountered during ICP-OES analysis: physical, chemical, and spectral.

Physical interferences

Physical interferences are defined as differences between the samples and calibration standards that affect sample transport or nebulization. These differences can include viscosity, density, or matrix (from the sample itself or the digestion/preservation procedure). Some solutions that overcome these issues include sample dilution and matrix matching. Internal standardization can help when the matrix is not entirely known. Standard addition is useful when the matrix is completely unknown and cannot be corrected using an external calibration.

Chemical interferences

Chemical interferences occur when there is a difference in the way that the sample and the calibration standard react in the plasma, resulting in unintended ionization, molecular formation, or plasma loading. Also, some elements (e.g., alkalis) suffer from ionization effects.

Several steps can be taken to mitigate chemical interferences. Adding an ionization buffer can help to mitigate the ionization effects for some elements. In the case of organic samples, oxygen (present in compressed air) can be added into the plasma along with the sample—keeping in mind that the addition of oxygen causes interferences in the lower range of the spectrum. Optimization of plasma parameters can help to reduce plasma loading.

Spectral interferences

Spectral interferences are the most common ICP-OES issue. There are three kinds of spectral interferences:

- Background shifts that originate from the matrix

- Adjacent interferences from other elements in the sample

- Direct spectral overlaps that occur when two wavelengths are so close together that they cannot be resolved

To correct for this issue, off-peak background corrections and also, sometimes, an inter-element correction, are used. Fullframes can help visualize intensity distributions on the photo detector and provide insight on spectral interferences emerging from other areas of the spectrum (figure 2).

Overcoming interferences

Internal standards

Internal standards are used to correct for physical differences in samples and standards by referencing all samples to the same element. A correction is then applied to the sample in accordance with the suppression or enhancement of signal experienced by the internal standard element. Typical internal standards for ICP-OES analyses are scandium and yttrium.

There are set requirements for the usability of an internal standard. The internal standards must be referenced to elements that will react the same way in the plasma; i.e., they are all atomic or ionic wavelengths. An element wavelength and its internal standard wavelength should have the same plasma view and slit; i.e., axial/axial and radial/radial, or UV/UV and VIS/VIS. The wavelength of the internal standard must be interference-free, the background correction must be used, and the same amount of internal standard must be added to all samples. When adding the internal standard online, an internal standard mixing kit can be used.

Method of standard addition

The method of standard addition (MSA) is used to overcome strong physical interferences that cannot be corrected for by an internal standard, or when there is an entirely unknown matrix with unknown effects on the plasma. A prerequisite for application of the MSA is calibration curve linearity. During the MSA, a potential sample is spiked with known additions of an element. The concentration in the sample can then be calculated via linear regression.

Inter-element correction

When direct spectral overlaps occur, an inter-element correction (IEC) can be applied to correct for these interferences. The inter-element correction applies a correction ratio, based on the apparent concentration of the interferent, to each analysis. Because the IEC is applying a ratio, it is dependent on the correct selection of background correction points and the existence of a linear relationship between the analyte and interferent.

Method validation

Quality control samples are used to ensure that the method is performing reliably and the generated data are valid. A number of different quality control tests can be performed during data analysis, including but not restricted to the following:

- Detection limit tests

These tests help decide whether the basic required detection limits are achieved. Also, they are used to identify if there is contamination or carryover from a previous sample. - Recovery tests

In a recovery test, a known concentration is analyzed and percent recovery is calculated. These tests are applied to determine if the calibration is still valid or if certified reference materials (CRMs) are in the required concentration range. - Paired sample tests

Paired samples are used to assess the reproducibility between two defined samples. The QC software monitors the first defined sample, then determines if the second sample is significantly above or below defined limits. Duplicate tests determine the relative percent difference (RPD) between two identical samples, and a serial dilution test determines if the sample matrix affects the data quality by changing the percent recovery after a certain dilution of the sample. - Spike tests

Spike tests generate information about the recovery of spiked samples; this in turns provides an idea about possible differences between calibration standards and samples that are caused by for example interferences. - Continuous tests

During analysis, certain parameters like internal standard recovery and relative standard deviation between analysis replicates are monitored to provide information about sample-related or sample introduction issues.

Automated method development

Certain software features facilitate method development by selecting wavelengths and plasma parameters according to the sample analyzed. One such example is the Element Finder plug-in of the Thermo Scientific Qtegra Intelligent Scientific Data Solution (ISDS) Software.

Qtegra (ISDS) Software for the Thermo Scientific iCAP 7000 Plus Series ICP-OES has an integrated method development tool consisting of two parts, the Plasma Optimization tool, and the Element Finder plug-in.

Plasma optimization

The Plasma Optimization tool optimizes the RF power and nebulizer gas flow based on the sample type (aqueous or organic). Plasma optimization can be performed to achieve optimal intensity and signal to background (or signal to square root of background) ratio. In the process, multiple wavelengths can be chosen to achieve optimal averaged parameters for all analytes.

Element finder

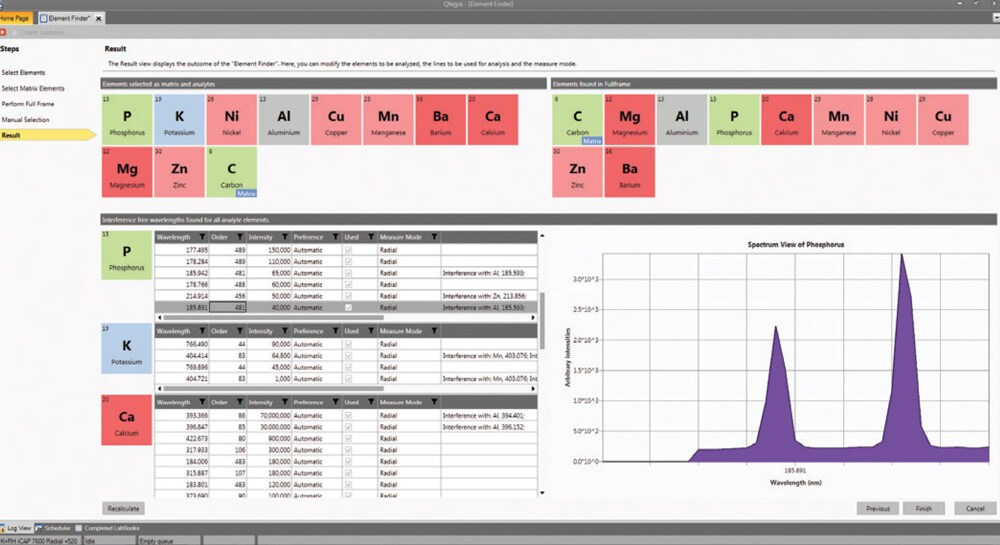

The Element Finder plug-in identifies wavelengths suitable for analysis based on the sample. This is performed either manually, by selecting analyte and matrix elements, or automatically, by running a series of Fullframes.

If the sample is known, the user picks the analyte and matrix elements. With the aid of a built-in wavelength library, the Element Finder plug-in then chooses those wavelengths that do not have any interferences with any of the other element wavelengths.

When the sample is completely unknown, the Element Finder plug-in can also be used to find the elements present in the sample. This is performed in just three easy steps. In the first step, multiple Fullframes of the sample are taken. The second step shows which elements were found and suggests a wavelength to use. A manual selection of preferred wavelengths is also possible. Interferences are shown in the subarray window to improve selection. In the third and final step, the results are imported in a method and can be used for measurement.

While manual method development requires multiple iterations of the process and an unknown amount of sample, the Element Finder plug-in requires fewer than five minutes of time and only eight milliliters of sample solution.

Spectroscopy Elemental & Isotope Analysis Resource Library

Learn how elements and their isotopes provide information about sample origin and identity in our library of applications notes, scientific posters, webinars, and more.