Search Thermo Fisher Scientific

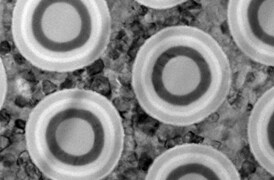

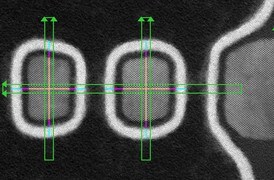

The miniaturization of semiconductor devices is continuing at an extraordinary rate. In order to accurately develop, characterize, and test these devices, advanced imaging and analysis techniques are needed. From simple, general tasks to advanced failure analysis (FA) techniques that need extremely precise voltage-contrast measurements on complex devices, scanning electron microscopy (SEM) imaging can provide you with a large variety of critical data for your semiconductor manufacturing needs.

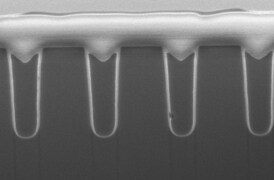

For example, higher accelerating voltages are often used to maximize signal and reduce time-to-data. These higher voltages were once acceptable because of the larger structural dimensions found in previous generation devices. However, as feature sizes continue to shrink due to device miniaturization, higher accelerating voltages are no longer appropriate, and lower voltages are necessary to accurately image smaller features. Low kV imaging also allows you to analyze working transistors without impacting their characteristics and helps you resolve layers without interference from the underlying sections. New materials also require low voltage to minimize beam damage.

Thermo Fisher Scientific offers a range of SEM instrumentation, including low-voltage tools ideally suited to analyze the next generation of semiconductor devices. This includes the versatile Thermo Scientific Prisma SEM and Thermo Scientific Quattro SEM, our general-purpose tools available with Thermo Scientific ChemiSEM Technology. We also offer high-quality, and low-kV imaging on the Thermo Scientific Apreo SEM, and high-contrast sub-nanometer imaging on the Thermo Scientific Verios XHR SEM. Please click through to the appropriate product pages below for more information.

Semiconductor Device Packaging

Advanced semiconductor device packaging requires new integration approaches and innovation in performance, power efficiency, area, and cost. See how Thermo Scientific failure analysis workflows provide fast, precise, and accurate time-to-data for device packaging development.

Semiconductor Pathfinding and Research

Advanced electron microscopy, focused ion beam, and associated analytical techniques for identifying viable solutions and design methods for the fabrication of high-performance semiconductor devices.

Semiconductor Failure Analysis

Increasingly complex semiconductor device structures result in more places for failure-inducing defects to hide. Our next-generation workflows help you localize and characterize subtle electrical issues that affect yield, performance, and reliability.

Physical and Chemical Characterization

Ongoing consumer demand drives the creation of smaller, faster, and cheaper electronic devices. Their production relies on high-productivity instruments and workflows that image, analyze, and characterize a broad range of semiconductor and display devices.

Power Semiconductor Device Analysis

Power devices pose unique challenges for localizing faults, primarily as a result of power device architecture and layout. Our power device analysis tools and workflows quickly pinpoint fault locations at operating conditions and provide precise, high-throughput analysis for characterization of materials, interfaces and device structures.

Display Module Failure Analysis

Evolving display technologies aim to improve display quality and light conversion efficiency to support applications in different industry sectors, while continuing to reduce production costs. Our process metrology, failure analysis and research and development solutions help display companies solve these challenges.

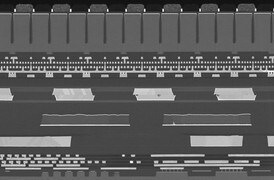

Yield Ramp and Metrology

We offer advanced analytical capabilities for defect analysis, metrology, and process control, designed to help increase productivity and improve yield across a range of semiconductor applications and devices.

Semiconductor Materials and Device Characterization

As semiconductor devices shrink and become more complex, new designs and structures are needed. High-productivity 3D analysis workflows can shorten device development time, maximize yield, and ensure that devices meet the future needs of the industry.

Electron microscopy services for

semiconductors

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.