Search Thermo Fisher Scientific

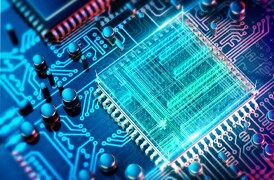

Semiconductor devices can fail for many reasons, leading to wasted time and increased costs for the manufacturer. Failures can result from excess current or voltage, ionizing radiation, mechanical stress, or large increases in temperature, which are the consequence of an uneven distribution of local power dissipation.

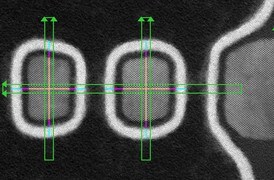

Steady-state and lock-in thermography are techniques that allow you to detect the temperature variations that lead to device failures. Of these methods, lock-in infrared (IR) thermography (LIT) offers much better signal-to-noise ratio, sensitivity, and feature resolution than steady-state thermography. LIT can be used in the failure analysis of semiconductor interconnects to locate line shorts, electrostatic discharge (ESD) defects, oxide damage, defective transistors and diodes, and device latch-ups.

LIT is an increasingly valuable technique for locating thermal faults in a broad range of semiconductor devices. The Thermo Scientific ELITE System is a powerful LIT tool that is particularly useful when combined with the Thermo Scientific Helios PFIB DualBeam for physical analysis, creating a highly efficient workflow. Learn more by exploring the product pages below.

Semiconductor Device Packaging

Advanced semiconductor device packaging requires new integration approaches and innovation in performance, power efficiency, area, and cost. See how Thermo Scientific failure analysis workflows provide fast, precise, and accurate time-to-data for device packaging development.

Semiconductor Pathfinding and Research

Advanced electron microscopy, focused ion beam, and associated analytical techniques for identifying viable solutions and design methods for the fabrication of high-performance semiconductor devices.

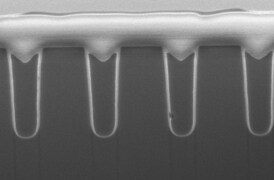

Semiconductor Failure Analysis

Increasingly complex semiconductor device structures result in more places for failure-inducing defects to hide. Our next-generation workflows help you localize and characterize subtle electrical issues that affect yield, performance, and reliability.

Physical and Chemical Characterization

Ongoing consumer demand drives the creation of smaller, faster, and cheaper electronic devices. Their production relies on high-productivity instruments and workflows that image, analyze, and characterize a broad range of semiconductor and display devices.

ESD Semiconductor Qualification

Every electrostatic discharge (ESD) control plan is required to identify devices that are sensitive to ESD. We offer a complete suite of test systems to help with your device qualification requirements.

Power Semiconductor Device Analysis

Power devices pose unique challenges for localizing faults, primarily as a result of power device architecture and layout. Our power device analysis tools and workflows quickly pinpoint fault locations at operating conditions and provide precise, high-throughput analysis for characterization of materials, interfaces and device structures.

Display Module Failure Analysis

Evolving display technologies aim to improve display quality and light conversion efficiency to support applications in different industry sectors, while continuing to reduce production costs. Our process metrology, failure analysis and research and development solutions help display companies solve these challenges.

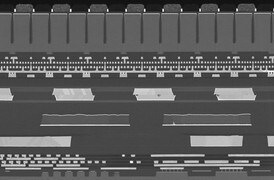

Yield Ramp and Metrology

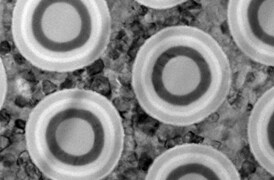

We offer advanced analytical capabilities for defect analysis, metrology, and process control, designed to help increase productivity and improve yield across a range of semiconductor applications and devices.

Semiconductor Materials and Device Characterization

As semiconductor devices shrink and become more complex, new designs and structures are needed. High-productivity 3D analysis workflows can shorten device development time, maximize yield, and ensure that devices meet the future needs of the industry.

Electron microscopy services for

semiconductors

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.