Search Thermo Fisher Scientific

DualBeam Microscopes

Helios 5 PXL PFIB Wafer DualBeam

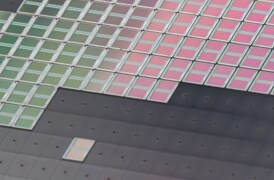

PFIB SEM for in-line metrology and process monitoring of advanced 3D NAND and DRAM devices.

The Thermo Scientific Helios 5 PXL Wafer DualBeam is a plasma focused ion beam scanning electron microscope (PFIB SEM) that redefines the standard for high-aspect-ratio through-stack metrology and structural verification. It features high-performance in-line metrology and process monitoring to quickly provide critical insights for process development and manufacturing engineers.

Designed to meet the in-line metrology and process control requirements of the fab, the Helios 5 PXL Wafer DualBeam significantly reduces time to data and enables the wafer to be returned to the line without being pulled and scrapped.

The Helios 5 PXL Wafer DualBeam is compatible with semiconductor factory automation, facilitating operator-free recipe-driven operations. This automation can support the high-throughput requirements of fab metrology and process monitoring – even on the most challenging structures.

Fast time to data

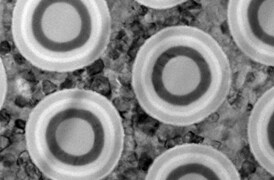

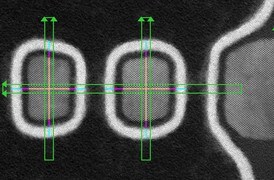

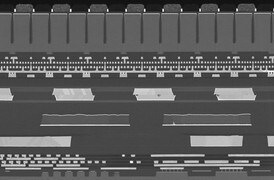

Utilizing the patented Thermo Scientific Elstar Electron Column with the high-performance PFIB2.0 xenon plasma ion column, the Helios 5 PXL Wafer DualBeam delivers high-resolution, high-contrast imaging. Obtain exact dimensional measurements of high-aspect-ratio 3D through-stack structures, data that is not easily accessible to conventional in-line metrology tools.

Faster yield learning and increased productivity

Fast, precise, large-area wafer level deprocessing, diagonal milling and cross sectioning of high-aspect-ratio structures. Advanced automation capabilities identify potential issues, accelerating process development and minimizing manufacturing disruptions.

World-class service, knowledge, and expertise

The Helios 5 PXL Wafer DualBeam is backed by our world-class service, knowledge, and expertise in advanced metrology sample preparation and failure analysis.

| Xe+ Plasma FIB Column |

|

| Elstar UHR Immersion Lens FESEM Column |

|

| Gas delivery |

|

| Wafer handling |

|

| Additional options |

|

The Thermo Scientific Helios DualBeam Family

The Thermo Scientific Helios DualBeam Family

Semiconductor Device Packaging

Advanced semiconductor device packaging requires new integration approaches and innovation in performance, power efficiency, area, and cost. See how Thermo Scientific failure analysis workflows provide fast, precise, and accurate time-to-data for device packaging development.

Memory Device Metrology and Analysis

Modern data demands are driving innovation in 3D NAND, DRAM and other memory structures. Our memory analysis tools and workflows offer high-productivity characterization so that manufacturers can meet performance, latency, and capacity demands.

Semiconductor Pathfinding and Research

Advanced electron microscopy, focused ion beam, and associated analytical techniques for identifying viable solutions and design methods for the fabrication of high-performance semiconductor devices.

Yield Ramp and Metrology

We offer advanced analytical capabilities for defect analysis, metrology, and process control, designed to help increase productivity and improve yield across a range of semiconductor applications and devices.

Semiconductor Failure Analysis

Increasingly complex semiconductor device structures result in more places for failure-inducing defects to hide. Our next-generation workflows help you localize and characterize subtle electrical issues that affect yield, performance, and reliability.

ESD Semiconductor Qualification

Every electrostatic discharge (ESD) control plan is required to identify devices that are sensitive to ESD. We offer a complete suite of test systems to help with your device qualification requirements.

Physical and Chemical Characterization

Ongoing consumer demand drives the creation of smaller, faster, and cheaper electronic devices. Their production relies on high-productivity instruments and workflows that image, analyze, and characterize a broad range of semiconductor and display devices.

Nanoprobing

As device complexity increases, so does the number of places defects have to hide. Nanoprobing provides the precise localization of electrical faults, which is critical for an effective transmission electron microscopy failure analysis workflow.

Optical Fault Isolation

Increasingly complex designs complicate fault and defect isolation in semiconductor manufacturing. Optical fault isolation techniques allow you to analyze the performance of electrically active devices to locate critical defects that cause device failure.

Thermal Fault Isolation

Uneven distribution of local power dissipation can cause large, localized increases in temperature, leading to device failure. We offer unique solutions for thermal fault isolation with high-sensitivity lock-in infrared thermography (LIT).

Semiconductor TEM Imaging and Analysis

Thermo Scientific transmission electron microscopes offer high-resolution imaging and analysis of semiconductor devices, enabling manufacturers to calibrate toolsets, diagnose failure mechanisms, and optimize overall process yields.

TEM Metrology

Advanced and automated TEM metrology routines deliver significantly greater precision than manual methods. This allows users to generate large amounts of statistically relevant data, with sub-angstrom-level specificity, that is free of operator bias.

Sample Preparation of Semiconductor Devices

Thermo Scientific DualBeam systems provide accurate TEM sample preparation for atomic-scale analysis of semiconductor devices. Automation and advanced machine learning technologies produce high-quality samples, at the correct location, and a low cost per sample.

SEM Metrology

Scanning electron microscopy provides accurate and reliable metrology data at nanometer scales. Automated ultra-high-resolution SEM metrology enables faster time-to-yield and time-to-market for memory, logic, and data storage applications.

Semiconductor Analysis and Imaging

Thermo Fisher Scientific offers scanning electron microscopes for every function of a semiconductor lab, from general imaging tasks to advanced failure analysis techniques requiring precise voltage-contrast measurements.

Device Delayering

Shrinking feature size, along with advanced design and architecture, results in increasingly challenging failure analysis for semiconductors. Damage-free delayering of devices is a critical technique for the detection of buried electrical faults and failures.

ESD Compliance Testing

Electrostatic discharge (ESD) can damage small features and structures in semiconductors and integrated circuits. We offer a comprehensive suite of test equipment which verifies that your devices meet targeted ESD compliance standards.

Nanoprobing

As device complexity increases, so does the number of places defects have to hide. Nanoprobing provides the precise localization of electrical faults, which is critical for an effective transmission electron microscopy failure analysis workflow.

Optical Fault Isolation

Increasingly complex designs complicate fault and defect isolation in semiconductor manufacturing. Optical fault isolation techniques allow you to analyze the performance of electrically active devices to locate critical defects that cause device failure.

Thermal Fault Isolation

Uneven distribution of local power dissipation can cause large, localized increases in temperature, leading to device failure. We offer unique solutions for thermal fault isolation with high-sensitivity lock-in infrared thermography (LIT).

Semiconductor TEM Imaging and Analysis

Thermo Scientific transmission electron microscopes offer high-resolution imaging and analysis of semiconductor devices, enabling manufacturers to calibrate toolsets, diagnose failure mechanisms, and optimize overall process yields.

TEM Metrology

Advanced and automated TEM metrology routines deliver significantly greater precision than manual methods. This allows users to generate large amounts of statistically relevant data, with sub-angstrom-level specificity, that is free of operator bias.

Sample Preparation of Semiconductor Devices

Thermo Scientific DualBeam systems provide accurate TEM sample preparation for atomic-scale analysis of semiconductor devices. Automation and advanced machine learning technologies produce high-quality samples, at the correct location, and a low cost per sample.

SEM Metrology

Scanning electron microscopy provides accurate and reliable metrology data at nanometer scales. Automated ultra-high-resolution SEM metrology enables faster time-to-yield and time-to-market for memory, logic, and data storage applications.

Semiconductor Analysis and Imaging

Thermo Fisher Scientific offers scanning electron microscopes for every function of a semiconductor lab, from general imaging tasks to advanced failure analysis techniques requiring precise voltage-contrast measurements.

Device Delayering

Shrinking feature size, along with advanced design and architecture, results in increasingly challenging failure analysis for semiconductors. Damage-free delayering of devices is a critical technique for the detection of buried electrical faults and failures.

ESD Compliance Testing

Electrostatic discharge (ESD) can damage small features and structures in semiconductors and integrated circuits. We offer a comprehensive suite of test equipment which verifies that your devices meet targeted ESD compliance standards.

Electron microscopy services for

semiconductors

To ensure optimal system performance, we provide you access to a world-class network of field service experts, technical support, and certified spare parts.