Search Thermo Fisher Scientific

FIB circuit edit and rapid prototyping

Time to market is a critical factor in the success of semiconductor devices. Manufacturing timelines are long and difficult to manage, so it is important that early production runs provide functional devices. Late discovery of design issues limiting device performance at final test can lead to months of delays in product introduction timelines while new mask sets are created, and new devices are manufactured.

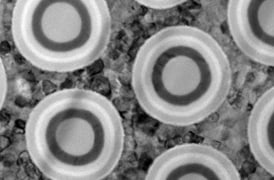

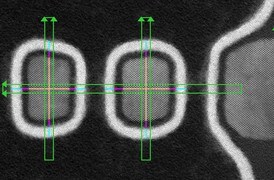

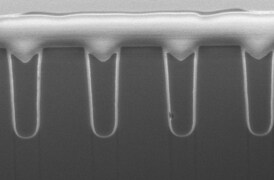

Circuit edit systems provide a solution to test and validate design changes, optimize performance, prototype, and scale functional devices for internal and external customer’s development, validation, and qualification. Circuit edit systems utilize high-resolution focused ion beams (FIBs) and advaced chemistries to perform “nano-surgery” on semi-conductor devices, cutting and creating connections within the device to correct design issues and return functioning products. These working devices keep projects on track without the costs and delays of new mask sets.

Circuit edit systems

With the Thermo Scientific Centrios and Centrios HX Circuit Edit Systems, you can manage program costs, avoid schedule delays, and accelerate time-to-market. The Centrios HX System is designed to meet the circuit editing needs of today’s most advanced semiconductor devices. The Centrios System provides circuit edit capability suitable for a wide range of applications where the required circuit edit performance can be delivered with an improved cost of ownership. Both systems are optimized for the modern, competitive technology world.

半導体のパスファインディングと開発

高性能半導体デバイス製造を可能にするソリューションや設計へ導く高度な電子顕微鏡、集束イオンビーム、および関連する分析手法。

歩留り改善と計測

当社は、幅広い半導体アプリケーションやデバイスの生産性向上と歩留り改善に寄与する、欠陥分析、計測、およびプロセス制御のための高度な分析機能を提供しています。

パワー半導体デバイス解析

電力用装置には、障害位置特定にかかわる特有の課題があります。これは主に、動力用装置のアーキテクチャとレイアウトを原因としています。当社のパワー半導体デバイス解析ツールとワークフローを使用すると、動作条件下の不良個所をすばやく特定し、材料、インターフェース、装置構造の高精度かつハイスループットの特性分析を行えます。

半導体材料およびデバイスの解析

半導体デバイスが微細化し複雑になるにつれて、新しい設計と構造が必要になります。生産性の高い3D解析ワークフローはデバイス開発時間の短縮や、歩留まりの最大化を実現し、デバイスが業界の将来のニーズを確実に満たすようにします。