Search Thermo Fisher Scientific

Steel microscopy

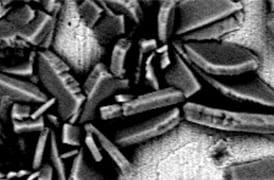

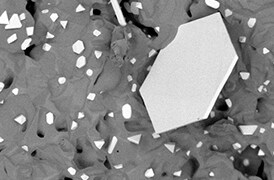

Metallurgists and researchers in steel manufacturing need scanning electron microscopy (SEM) and energy dispersive X-ray spectroscopy (EDS) data for failure analysis and process improvement. The Thermo Scientific Phenom ParticleX Steel Desktop SEM is a multi-purpose desktop SEM enabling failure analysis and automated characterization of non-metallic inclusions in steel.

Steel inclusion analysis

This versatile solution for high-quality imaging and elemental analysis of steel samples provides the data needed for today's efficient production of high-value steels. Rapid, easy analysis allows you to quickly respond to customer claims of faults, failures, etc., while the automated steel inclusion analysis provides you insight into the steelmaking process.

Small Footprint

The Phenom ParticleX Steel Desktop SEM needs only standard wall power, allowing it to extend the capabilities of analytical labs without infrastructure changes. The integrated EDS enables users to simply click-and-go to work with elemental mapping and line scan, which shows the quantified element distribution in a line plot.

Ease of use

The user interface is based on the proven ease-of-use technology applied in the successful Phenom Desktop SEMs. The interface enables both existing and new customers to quickly become familiar with the system with a minimum of training. The high brightness of the unique CeB6 source aids in capturing high image detail as well as rapid automated analysis of steel inclusions.

Future-proof

While the default classification rules and analysis recipe allow you to quickly get started with steel inclusion analysis, the classification and recipes are fully customizable. This allows you to capture new insights in updated recipes

Steel inclusion analysis software

Building on years of experience in steel inclusion analysis, default classification rules and analysis recipes allow users to quickly capture valuable data.

ChemiSEM Technology

Thermo Scientific ChemiSEM Technology revolutionizes and simplifies EDS analysis by fully integrating SEM and EDS functions into a single, cohesive user interface. Based on live quantification and building on decades of expertise in EDS analysis, the technology provides elemental information quickly and easily, guaranteeing reliable results in less time. ChemiSEM Technology now comes with a powerful new feature: ChemiPhase. ChemiPhase identifies unique phases with a big data approach, finding minor and trace elements while eliminating user bias and reducing possible mistakes.

Electron optical magnification range |

|

Light optical magnification |

|

Resolution |

|

Image resolution options |

|

Acceleration voltages |

|

Vacuum levels |

|

Detector |

|

Sample size |

|

Sample loading time |

|

デスクトップSEMブログ

使いやすさを犠牲にすることなく、走査電子顕微鏡の優れた能力を活用できます。走査電子顕微鏡の詳細情報と、デスクトップSEMが最適な方法で研究を補助できる理由を、PhenomデスクトップSEMブログでご確認ください。

See how the Phenom ParticleX Steel Desktop SEM performs in the real world with application notes, webinars, and more.

| SEM EDX Analysis of Inclusions in Steel Using ParticleX Desktop SEM webinarWatch webinar |

On-demand webinar: New Phenom ParticleX Steel Desktop SEM

The Phenom ParticleX Steel Desktop SEM features integrated EDS and software specifically designed for steel manufacturing applications, such as fault and failure analysis, as well as quantitative characterization of inclusions. Register below to watch our recorded webinar and learn more about how the Phenom ParticleX Steel Desktop SEM with EDS enables precise control of the manufacturing process, in turn producing higher quality material.

Webinar: Scanning electron microscopy: selecting the right technology for your needs

This on-demand webinar has been designed to help you decide which SEM best meets your unique needs. We present an overview of Thermo Fisher Scientific SEM technology for multi-user research labs and focus on how these wide-ranging solutions deliver performance, versatility, in situ dynamics and faster time to results. Watch this webinar if you are interested in:

- How the needs for different microanalysis modalities are met (EDX, EBSD, WDS, CL, etc.).

- How samples are characterized in their natural state without the need for sample preparation.

- How new advanced automation allows researchers to save time and increase productivity.

Watch on-demand: Particle Analysis Applications Using Desktop SEM Webinar Series

In each on-demand webinar, our expert will focus on one particular analysis application and how the Phenom ParticleX Desktop SEM overcomes some of the most common challenges. See the abstracts for individual sessions below.

- How to certify your NCM powder quality with SEM+EDS

- Electron-microscope-grade cleanliness in electronics

- Speed up your automated gunshot residue analysis

- Technical cleanliness analysis with an SEM: Why?

- Understand your steel with automated inclusion analysis

- One tool for complete AM powder characterization

Phenom ParticleX Steel Desktop SEM inclusion analysis short demonstration.

ParticleX Steel Desktop SEM - Workflow introduction.

Phenom ParticleX Steel analysis of inclusions.

On-demand webinar: New Phenom ParticleX Steel Desktop SEM

The Phenom ParticleX Steel Desktop SEM features integrated EDS and software specifically designed for steel manufacturing applications, such as fault and failure analysis, as well as quantitative characterization of inclusions. Register below to watch our recorded webinar and learn more about how the Phenom ParticleX Steel Desktop SEM with EDS enables precise control of the manufacturing process, in turn producing higher quality material.

Webinar: Scanning electron microscopy: selecting the right technology for your needs

This on-demand webinar has been designed to help you decide which SEM best meets your unique needs. We present an overview of Thermo Fisher Scientific SEM technology for multi-user research labs and focus on how these wide-ranging solutions deliver performance, versatility, in situ dynamics and faster time to results. Watch this webinar if you are interested in:

- How the needs for different microanalysis modalities are met (EDX, EBSD, WDS, CL, etc.).

- How samples are characterized in their natural state without the need for sample preparation.

- How new advanced automation allows researchers to save time and increase productivity.

Watch on-demand: Particle Analysis Applications Using Desktop SEM Webinar Series

In each on-demand webinar, our expert will focus on one particular analysis application and how the Phenom ParticleX Desktop SEM overcomes some of the most common challenges. See the abstracts for individual sessions below.

- How to certify your NCM powder quality with SEM+EDS

- Electron-microscope-grade cleanliness in electronics

- Speed up your automated gunshot residue analysis

- Technical cleanliness analysis with an SEM: Why?

- Understand your steel with automated inclusion analysis

- One tool for complete AM powder characterization

Phenom ParticleX Steel Desktop SEM inclusion analysis short demonstration.

ParticleX Steel Desktop SEM - Workflow introduction.

Phenom ParticleX Steel analysis of inclusions.

電子顕微鏡を使用したプロセス制御

近年の産業では、確かなプロセス制御によって維持される優れた品質とスループットの両立が求められています。専用の自動化ソフトウェアを搭載したSEMおよびTEMツールは、プロセスモニタリングおよびプロセス改善のための迅速なマルチスケール情報を提供します。

品質管理と不良解析

近年の産業では、品質管理と品質保証が不可欠です。私たちは、欠陥をマルチスケールかつ多モードで分析可能なEMおよび分光ツールを提供しており、これらにより得られる信頼性の高い十分な情報によりプロセス制御および改善のための決定が可能となります。

3D材料解析

多くの場合、材料の開発にはマルチスケールの3D解析が必要です。DualBeam装置により、大量の連続スライスと、その後のナノメートルスケールでのSEMイメージングが可能となり、試料の高品質な3D再構成処理を行うことができます。

_Technique_800x375_144DPI.jpg)

EDS元素分析

EDSは、電子顕微鏡観察に不可欠な組成情報を提供します。特に、当社独自のSuper-XおよびDual-X検出器システムはSTEM-EDS分析の速度や感度を向上させるため、材料の研究に必要な元素分布情報が入手しやすくなります。

_Technique_800x375_144DPI.jpg)

3D EDSトモグラフィー

現代の材料研究は、3次元のナノスケール分析にますます依存しています。3Dの電子顕微鏡解析およびエネルギー分散型X線分光法を使用することにより、全元素の組成情報を含む微細構造の3D解析が可能になります。

EDSによる原子分解能元素マッピング

原子分解能EDSでは、個々の原子のレベルで元素を識別できるため、優れた高分解能の組成情報が得られます。高分解能S/TEMイメージングとの組み合わせにより、試料中の原子構成を正確に観察できます。

3D材料解析

多くの場合、材料の開発にはマルチスケールの3D解析が必要です。DualBeam装置により、大量の連続スライスと、その後のナノメートルスケールでのSEMイメージングが可能となり、試料の高品質な3D再構成処理を行うことができます。

_Technique_800x375_144DPI.jpg)

EDS元素分析

EDSは、電子顕微鏡観察に不可欠な組成情報を提供します。特に、当社独自のSuper-XおよびDual-X検出器システムはSTEM-EDS分析の速度や感度を向上させるため、材料の研究に必要な元素分布情報が入手しやすくなります。

_Technique_800x375_144DPI.jpg)

3D EDSトモグラフィー

現代の材料研究は、3次元のナノスケール分析にますます依存しています。3Dの電子顕微鏡解析およびエネルギー分散型X線分光法を使用することにより、全元素の組成情報を含む微細構造の3D解析が可能になります。

EDSによる原子分解能元素マッピング

原子分解能EDSでは、個々の原子のレベルで元素を識別できるため、優れた高分解能の組成情報が得られます。高分解能S/TEMイメージングとの組み合わせにより、試料中の原子構成を正確に観察できます。